Page 248 - Natural Antioxidants, Applications in Foods of Animal Origin

P. 248

Methods and Their Applications for Measuring 227

VetBooks.ir

Raw Frozen! Thawed Pork 85% lean Sausage Colorimetry

PVC overwrapped styrofoam trays

40.00 .------------

Iii

....

0

.!: 35.00 -----T----------

~

~0

~ ~ 30.00 +--___: .. !'!!!!!!!!,;;;a;; ...... ~ .... ,..;:::---,

Ea::

·c u ~Control, w/o antiox.

-§ ~ 25.00 +-------------.3o~ - • Rosemary Extract

* u ....

::I

u 5l 20 00 +------------- ......... BHAIBHT

....

.

..r:::

~

~ 15.00 +---.,----,------,-----,

T=O 2 4 6 8

Weeks Stored in +5°F (-l5°C) to +l0°F (-l2°C) Freezer

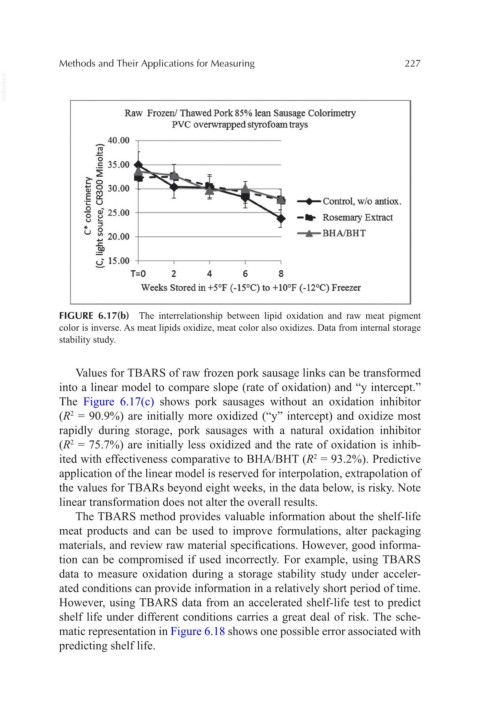

FIGURE 6.17(b) The interrelationship between lipid oxidation and raw meat pigment

color is inverse. As meat lipids oxidize, meat color also oxidizes. Data from internal storage

stability study.

Values for TBARS of raw frozen pork sausage links can be transformed

into a linear model to compare slope (rate of oxidation) and “y intercept.”

The Figure 6.17(c) shows pork sausages without an oxidation inhibitor

(R = 90.9%) are initially more oxidized (“y” intercept) and oxidize most

2

rapidly during storage, pork sausages with a natural oxidation inhibitor

(R = 75.7%) are initially less oxidized and the rate of oxidation is inhib-

2

ited with effectiveness comparative to BHA/BHT (R = 93.2%). Predictive

2

application of the linear model is reserved for interpolation, extrapolation of

the values for TBARs beyond eight weeks, in the data below, is risky. Note

linear transformation does not alter the overall results.

The TBARS method provides valuable information about the shelf-life

meat products and can be used to improve formulations, alter packaging

materials, and review raw material specifications. However, good informa-

tion can be compromised if used incorrectly. For example, using TBARS

data to measure oxidation during a storage stability study under acceler-

ated conditions can provide information in a relatively short period of time.

However, using TBARS data from an accelerated shelf-life test to predict

shelf life under different conditions carries a great deal of risk. The sche-

matic representation in Figure 6.18 shows one possible error associated with

predicting shelf life.