Page 1051 - Flipbook_SolidDesignSoutheast2020

P. 1051

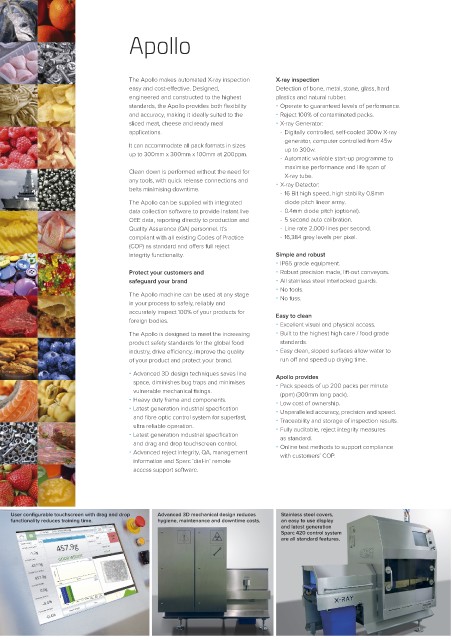

Apollo

The Apollo makes automated X-ray inspection X-ray inspection

easy and cost-effective. Designed, Detection of bone, metal, stone, glass, hard

engineered and constructed to the highest plastics and natural rubber.

standards, the Apollo provides both flexibility • Operate to guaranteed levels of performance.

and accuracy, making it ideally suited to the • Reject 100% of contaminated packs.

sliced meat, cheese and ready meal • X-ray Generator:

applications. - Digitally controlled, self-cooled 300w X-ray

generator, computer controlled from 45w

It can accommodate all pack formats in sizes

up to 300w.

up to 300mm x 300mm x 100mm at 200ppm.

- Automatic variable start-up programme to

maximise performance and life span of

Clean down is performed without the need for

X-ray tube.

any tools, with quick release connections and

• X-ray Detector:

belts minimising downtime.

- 16 Bit high speed, high stability 0.8mm

The Apollo can be supplied with integrated diode pitch linear array.

data collection software to provide instant live - 0.4mm diode pitch (optional).

OEE data, reporting directly to production and - 5 second auto calibration.

Quality Assurance (QA) personnel. It’s - Line rate 2,000 lines per second.

compliant with all existing Codes of Practice - 16,384 grey levels per pixel.

(COP) as standard and offers full reject

integrity functionality. Simple and robust

• IP65 grade equipment.

Protect your customers and • Robust precision made, lift-out conveyors.

safeguard your brand • All stainless steel interlocked guards.

• No tools.

The Apollo machine can be used at any stage

• No fuss.

in your process to safely, reliably and

accurately inspect 100% of your products for

Easy to clean

foreign bodies.

• Excellent visual and physical access.

The Apollo is designed to meet the increasing • Built to the highest high care / food grade

product safety standards for the global food standards.

industry, drive efficiency, improve the quality • Easy clean, sloped surfaces allow water to

of your product and protect your brand. run off and speed up drying time.

• Advanced 3D design techniques saves line

Apollo provides

space, diminishes bug traps and minimises

• Pack speeds of up 200 packs per minute

vulnerable mechanical fixings.

(ppm) (300mm long pack).

• Heavy duty frame and components.

• Low cost of ownership.

• Latest generation industrial specification

• Unparalleled accuracy, precision and speed.

and fibre optic control system for superfast,

• Traceability and storage of inspection results.

ultra reliable operation.

• Fully auditable, reject integrity measures

• Latest generation industrial specification

as standard.

and drag and drop touchscreen control.

• Online test methods to support compliance

• Advanced reject integrity, QA, management

with customers’ COP.

information and Sparc ‘dial-in’ remote

access support software.

User configurable touchscreen with drag and drop Advanced 3D mechanical design reduces Stainless steel covers,

functionality reduces training time. hygiene, maintenance and downtime costs. an easy to use display

and latest generation

Sparc 420 control system

are all standard features.