Page 1055 - Flipbook_SolidDesignSoutheast2020

P. 1055

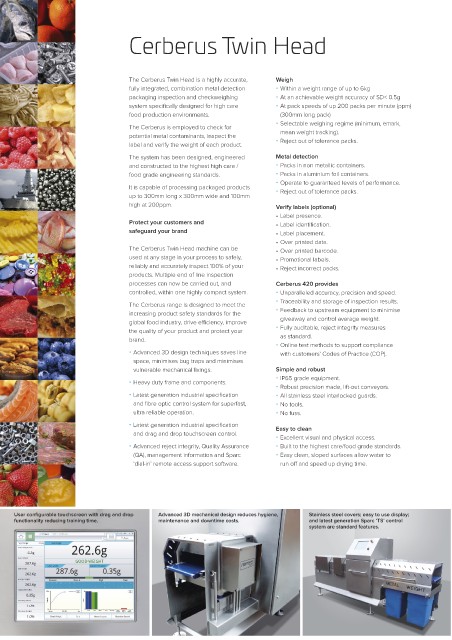

Cerberus Twin Head

The Cerberus Twin Head is a highly accurate, Weigh

fully integrated, combination metal detection • Within a weight range of up to 6kg

packaging inspection and checkweighing • At an achievable weight accuracy of SD< 0.5g

system specifically designed for high care • At pack speeds of up 200 packs per minute (ppm)

food production environments. (300mm long pack)

• Selectable weighing regime (minimum, emark,

The Cerberus is employed to check for

mean weight tracking).

potential metal contaminants, inspect the

• Reject out of tolerance packs.

label and verify the weight of each product.

The system has been designed, engineered Metal detection

and constructed to the highest high care / • Packs in non metallic containers.

food grade engineering standards. • Packs in aluminium foil containers.

• Operate to guaranteed levels of performance.

It is capable of processing packaged products

• Reject out of tolerance packs.

up to 300mm long x 300mm wide and 100mm

high at 200ppm.

Verify labels (optional)

• Label presence.

Protect your customers and

• Label identification.

safeguard your brand

• Label placement.

• Over printed data.

The Cerberus Twin Head machine can be

• Over printed barcode.

used at any stage in your process to safely,

• Promotional labels.

reliably and accurately inspect 100% of your

• Reject incorrect packs.

products. Multiple end of line inspection

processes can now be carried out, and Cerberus 420 provides

controlled, within one highly compact system. • Unparalleled accuracy, precision and speed.

• Traceability and storage of inspection results.

The Cerberus range is designed to meet the

• Feedback to upstream equipment to minimise

increasing product safety standards for the

giveaway and control average weight.

global food industry, drive efficiency, improve

• Fully auditable, reject integrity measures

the quality of your product and protect your

as standard.

brand.

• Online test methods to support compliance

• Advanced 3D design techniques saves line

with customers’ Codes of Practice (COP).

space, minimises bug traps and minimises

vulnerable mechanical fixings. Simple and robust

• IP65 grade equipment.

• Heavy duty frame and components.

• Robust precision made, lift-out conveyors.

• Latest generation industrial specification • All stainless steel interlocked guards.

and fibre optic control system for superfast, • No tools.

ultra reliable operation. • No fuss.

• Latest generation industrial specification

Easy to clean

and drag and drop touchscreen control.

• Excellent visual and physical access.

• Advanced reject integrity, Quality Assurance • Built to the highest care/food grade standards.

(QA), management information and Sparc • Easy clean, sloped surfaces allow water to

‘dial-in’ remote access support software. run off and speed up drying time.

User configurable touchscreen with drag and drop Advanced 3D mechanical design reduces hygiene, Stainless steel covers; easy to use display;

functionality reducing training time. maintenance and downtime costs. and latest generation Sparc ‘TS’ control

system are standard features.