Page 1874 - Flipbook_SolidDesignSoutheast2020

P. 1874

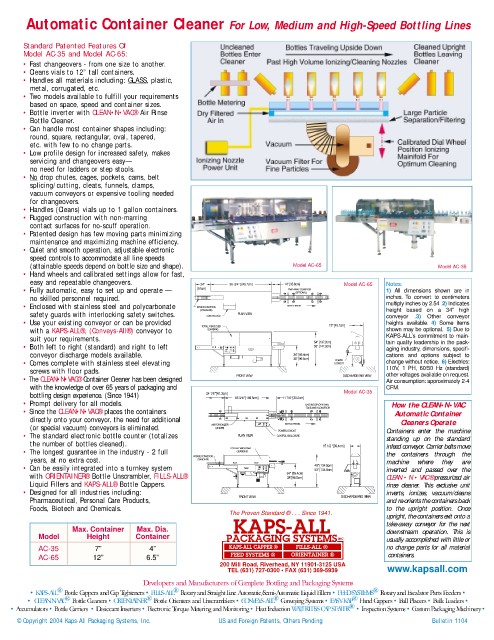

Automatic Container Cleaner For Low, Medium and High-Speed Bottling Lines

Standard Patented Features Of

Model AC-35 and Model AC-65:

• Fast changeovers - from one size to another.

• Cleans vials to 12” tall containers.

• Handles all materials including: GLASS, plastic,

metal, corrugated, etc.

• Two models available to fulfill your requirements

based on space, speed and container sizes.

• Bottle inverter with CLEAN•N•VAC® Air Rinse

Bottle Cleaner.

• Can handle most container shapes including:

round, square, rectangular, oval, tapered,

etc. with few to no change parts.

• Low profile design for increased safety, makes

servicing and changeovers easy—

no need for ladders or step stools.

• No drop chutes, cages, pockets, cams, belt

splicing/cutting, cleats, funnels, clamps,

vacuum conveyors or expensive tooling needed

for changeovers.

• Handles (Cleans) vials up to 1 gallon containers.

• Rugged construction with non-marring

contact surfaces for no-scuff operation.

• Patented design has few moving parts minimizing

maintenance and maximizing machine efficiency.

• Quiet and smooth operation, adjustable electronic

speed controls to accommodate all line speeds

(attainable speeds depend on bottle size and shape). Model AC-65 Model AC-35

• Hand wheels and calibrated settings allow for fast,

easy and repeatable changeovers. 24" 96 -3/4" [245.7cm] 14" [35.6cm] Model AC-65 Notes:

• Fully automatic, easy to set up and operate — [61cm] TAKE-AWAY CONVEYOR 1) All dimensions shown are in

(OPTIONAL)

no skilled personnel required. inches. To convert to centimeters

multiply inches by 2.54 2) Indicates

• Enclosed with stainless steel and polycarbonate INTAKE CONVEYOR BOTTLE TRAVEL

(STANDARD) height based on a 34” high

safety guards with interlocking safety switches. CONTROL BOX PLAN VIEW conveyor .3) Other conveyor

• Use your existing conveyor or can be provided heights available. 4) Some items

TOTALLY ENCLOSED 18" [45.7cm]

with a KAPS-ALL®, (Conveys-All®) conveyor to GUARDING shown may be optional. 5) Due to

KAPS-ALL’s commitment to main-

suit your requirements.

54" [137.2cm] tain quality leadership in the pack-

• Both left to right (standard) and right to left START EMER E C N G Y 30 40 20 0 10 50 60 70 100 90 80 30 40 0 10 20 50 60 70 90 80 100 58" [147.3cm]

PACKAGING THE PROVEN STANDARD...SINCE 1941 KAPS-ALL CAPPER FEED SYSTEMS RIVERHEAD, NY 11901 U.S.A. R S T O SYSTEMS R ORIENTAINER FILLS-ALL R P R INC. R R OFF ON OFF ON VACUUM MOTOR OFF ON OFF ON STATIC ELIMINATOR aging industry, dimensions, specifi-

10 30 20 40 50 60 70 80 90 ON I ON

MANUFACTURERS OF COMPLETE BOTTLING AND PACKAGING SYSTEMS CLEAN-N-VAC R BOTTLE COUNTER 0 US AND FOREIGN PATENTS, OTHERS PENDING CARRIER BELTS 100 LOCK-OUT Main Power OFF OFF O

conveyor discharge models available. 34" [86.4cm] cations and options subject to

38" [96.5cm] POWER

• Comes complete with stainless steel elevating LOCKOUT change without notice. 6) Electrics:

110V, 1 PH, 60/50 Hz (standard)

screws with floor pads.

FRONT VIEW DISCHARGE END VIEW other voltages available on request.

• The CLEAN•N•VAC® Container Cleaner has been designed Air consumption: approximately 2-4

with the knowledge of over 65 years of packaging and Model AC-35 CFM.

bottling design experience. (Since 1941) 24 1/8 "[61.3cm]

66 3/4 "[169.5cm] 11 7/8 "[30.2cm]

• Prompt delivery for all models. EXISTING OR OPTIONAL How the CLEAN•N•VAC

TAKE AWAY CONVEYOR

• Since the CLEAN•N•VAC® places the containers

L C Automatic Container

directly onto your conveyor, the need for additional

START ME GE R S T O NCY P E 40 10 0 20 30 CONVEYOR INTAKE 60 50 100 90 80 70 40 30 10 SEPARATOR 0 20 50 BOTTLE 60 90 100 70 80 Cleaners Operate

AIR FOR IONIZER CLEAN-N-VAC MANUFACTURERS OF COMPLETE BOTTLING AND PACKAGING SYSTEMS PACKAGING THE PROVEN STANDARD...SINCE 1941 KAPS-ALL CAPPER FEED SYSTEMS RIVERHEAD, NY 11901 U.S.A. SYSTEMS R R R R ORIENTAINER FILLS-ALL R INC. R R OFF ON MOTOR VACUUM BOTTLE COUNTER OFF ON 20 30 ELIMINATOR 40 10 0 US AND FOREIGN PATENTS, OTHERS PENDING 50 STATIC BELTS CARRIER 70 80 60 90 100 LOCK-OUT Main Power BOTTLE TRAVEL

(or special vacuum) conveyors is eliminated. (UNDER)

POWER LOCKOUT Containers enter the machine

• The standard electronic bottle counter (totalizes PLAN VIEW CONTROL ENCLOSURE standing up on the standard

the number of bottles cleaned). 15 1/2 "[39.4cm] infeed conveyor. Carrier belts move

TOTALLY ENCLOSED

• The longest guarantee in the industry - 2 full GUARDING the containers through the

INTAKE CONVEYOR

years, at no extra cost. STANDARD machine where they are

49" [124.5cm]

• Can be easily integrated into a turnkey system THE PROVEN STANDARD...SINCE 1941 PACKAGING FEED SYSTEMS KAPS-ALL CAPPER RIVERHEAD, NY 11901 U.S.A. S T R R SYSTEMS R FILLS-ALL ORIENTAINER P O R R R INC. 20 0 10 CONVEYOR INTAKE OFF ON VACUUM MOTOR 80 100 90 20 10 0 SEPARATOR BOTTLE OFF ON ELIMINATOR STATIC 80 100 90 OFF ON inverted and passed over the

50

40

30

G

ER EN

CY

EM

START

70

30

60

50

40

70

60

CLEAN-N-VAC R BOTTLE COUNTER 30 20 40 BELTS 0 10 CARRIER 80 70 60 50 90 100 LOCK-OUT LOCK-OUT Main Power Main Power 53" [134.6cm] 0

MANUFACTURERS OF COMPLETE BOTTLING AND PACKAGING SYSTEMS US AND FOREIGN PATENTS, OTHERS PENDING 34" [86.4cm]

with ORIENTAINER® Bottle Unscrambler, FILLS-ALL® 38"[96.5cm] CLEAN • N • VAC® pressurized air

Liquid Fillers and KAPS-ALL® Bottle Cappers. rinse cleaner. This exclusive unit

• Designed for all industries including: inverts, ionizes, vacuum/cleans

FRONT VIEW DISCHARGE END VIEW

Pharmaceutical, Personal Care Products, and re-orients the containers back

Foods, Biotech and Chemicals. to the upright position. Once

The Proven Standard ® . . . Since 1941.

upright, the containers exit onto a

take-away conveyor for the next

Max. Container Max. Dia. downstream operation. This is

Model Height Container

usually accomplished with little or

AC-35 7” 4” no change parts for all material

AC-65 12” 6.5” containers.

200 Mill Road, Riverhead, NY 11901-3125 USA

TEL (631) 727-0300 • FAX (631) 369-5939 www.kapsall.com

Developers and Manufacturers of Complete Bottling and Packaging Systems

®

®

®

• KAPS-ALL Bottle Cappers and Cap Tighteners • FILLS-ALL Rotary and Straight Line Automatic/Semi-Automatic Liquid Fillers • FEED SYSTEMS Rotary and Escalator Parts Feeders •

®

®

®

®

• CLEAN-N-VAC Bottle Cleaners • ORIENTAINER Bottle Orienters and Unscramblers • CONVEYS-ALL Conveying Systems • EASY-KAP Hand Cappers • Ball Placers • Bulk Loaders •

®

• Accumulators • Bottle Carriers • Desiccant Inserters • Electronic Torque Metering and Monitoring • Heat Induction WATERLESS CAP SEALER • Inspection Systems • Custom Packaging Machinery •

© Copyright 2004 Kaps-All Packaging Systems, Inc. US and Foreign Patents, Others Pending Bulletin 1104