Page 1872 - Flipbook_SolidDesignSoutheast2020

P. 1872

Call for more information and/or application assistance

Kaps-All Packaging Systems, Inc., 200 Mill Road, Riverhead, NY 11901-3125 USA

Tel. (631) 727-0300 • Fax. (631) 369-5939 • www.kapsall.com

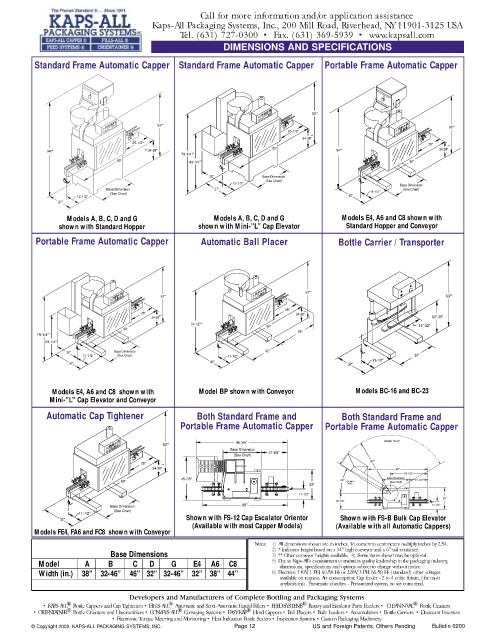

DIMENSIONS AND SPECIFICATIONS

Standard Frame Automatic Capper Standard Frame Automatic Capper Portable Frame Automatic Capper

63"*

63"*

63"*

25-1/2 "

**

34-38"

25-1/2 " 28"

90" 34-38" **

94"* ** 34-38" 94"*

79-1/4 "*

90" 90"

90"

43-1/4 "*

C L

L 26" Base Dimension C L

C L C (See Chart)

12-1/2

"

Base Dimension

Base Dimension 27" 11-1/2 " (See Chart)

(See Chart)

12-1/2 " 32"

27"

Models A, B, C, D and G Models A, B, C, D and G Models E4, A6 and C8 shown with

shown with Standard Hopper shown with Mini-”L” Cap Elevator Standard Hopper and Conveyor

Portable Frame Automatic Capper Automatic Ball Placer Bottle Carrier / Transporter

63"*

63"* 63"*

28"

28" 34-38" **

34-38" ** 34"-39"

74-1/2"*

90" 14"-22"

90"

29"

79-1/4 "*

43-1/4 "*

C L C L

Base Dimension 32" C L

26"

11-1/2 " (See Chart) 11-1/2 " 32"

11-1/2"

32"

32" 32"

Models E4, A6 and C8 shown with Model BP shown with Conveyor Models BC-16 and BC-23

Mini-”L” Cap Elevator and Conveyor

Automatic Cap Tightener Both Standard Frame and Both Standard Frame and

Portable Frame Automatic Capper Portable Frame Automatic Capper

96-3/4" MODEL "FS-B"

63"*

Base Dimension 27-5/8"

(See Chart)

88"*

28"

**

34-38" 90"

56-1/2"

45-7/8" 30° Base Dimension 27-3/4"

90" TYP. BOTH (See Chart)

32"

SIDES

C L

11-1/2"

32"

C L 24-1/8" C L

Base Dimension 90" 11-1/2"

(See Chart)

11-1/2 "

32" Shown with FS-12 Cap Escalator Orientor Shown with FS-B Bulk Cap Elevator

(Available with most Capper Models) (Available with all Automatic Cappers)

Models FE4, FA6 and FC8 shown with Conveyor

Notes: 1) All dimensions shown are in inches. To convert to centimeters multiply inches by 2.54.

2) * Indicates height based on a 34” high conveyor and a 6” tall container.

Base Dimensions 3) ** Other conveyor heights available. 4) Some items shown may be optional.

5) Due to Kaps-All’s commitment to maintain quality leadership in the packaging industry,

Model A B C D G E4 A6 C8 dimensions, specifications and options subject to change without notice.

Width (in.) 38” 32-46” 46” 32” 32-46” 32” 38” 44” 6) Electrics: 110V, 1 PH, 60/50 Hz or 220V, 3 PH, 60/50 Hz (standard) other voltages

available on request. Air consumption: Cap feeder - 2 to 4 cubic ft/min, (for most

applications). Pneumatic clutches - Pressurized system, no air consumed.

Developers and Manufacturers of Complete Bottling and Packaging Systems

® ® ® ®

• KAPS-ALL Bottle Cappers and Cap Tighteners • FILLS-ALL Automatic and Semi-Automatic Liquid Fillers • FEED SYSTEMS Rotary and Escalator Parts Feeders • CLEAN-N-VAC Bottle Cleaners

• ORIENTAINER ® Bottle Orienters and Unscramblers • CONVEYS-ALL ® Conveying Systems • EASY-KAP ® Hand Cappers • Ball Placers • Bulk Loaders • Accumulators • Bottle Carriers • Desiccant Inserters

• Electronic Torque Metering and Monitoring • Heat Induction Bottle Sealers • Inspection Systems • Custom Packaging Machinery

© Copyright 2000, KAPS-ALL PACKAGING SYSTEMS, INC. Page 12 US and Foreign Patents, Others Pending Bulletin 0200