Page 1877 - Flipbook_SolidDesignSoutheast2020

P. 1877

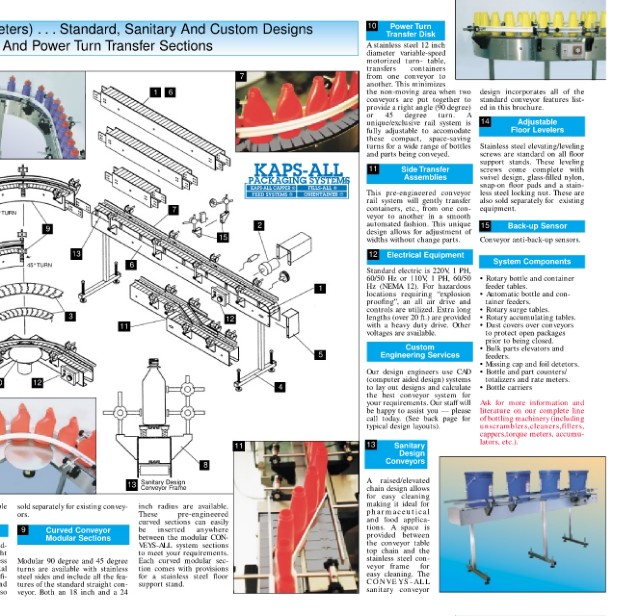

Close To 60 Years Experience Conveyors From 3 Ft. (1 Meter) To 38 Ft. (12 Meters) . . . Standard, Sanitary And Custom Designs 10 Power Turn

Designing And Engineering Transfer Disk

Quality Conveyors Featuring Straight, Curved, Side Transfer, And Power Turn Transfer Sections A stainless steel 12 inch

Fast And Easy Assembly, diameter variable-speed

Versatility And Affordability motorized turn- table,

transfers containers

User Friendly Modular, Expandable Conveyors, 7 7 from one conveyor to

another. This minimizes

CONVEYS-ALL™ modular con- Conveying Systems And Conveying 1 6 the non-moving area when two design incorporates all of the

veyor designs require no tools conveyors are put together to standard conveyor features list-

for adjustments. Standard com- Parts For Existing Conveyors provide a right angle (90 degree) ed in this brochure.

ponents are used for simple and or 45 degree turn. A 14

complete in-house installation unique/exclusive rail system is Adjustable

eliminating expensive downtime pre-tested systems are then bro- Patented, Fully Adjustable fully adjustable to accomodate Floor Levelers

and ensuring easy maintenance. ken down for crating purposes). Conveyor Rail Post, With Single these compact, space-saving

The pre-assembled modules are Units can be shipped common Rails, Double Rails turns for a wide range of bottles Stainless steel elevating/leveling

easily connected together. The carrier or express service or and parts being conveyed. screws are standard on all floor

standard stainless steel frame depending upon size. 3 Position Conveyor support stands. These leveling

eliminates painted surfaces, alu- 2 Conveyor Drives Rail Post 7 8 KAPS-ALL 11 Side Transfer screws come complete with

minum extrusions and crudely PACKAGING SYSTEMS INC. Assemblies swivel design, glass-filled nylon,

welded non-sanitary systems 1 KAPS-ALL CAPPER ® FILLS-ALL ® snap-on floor pads and a stain-

presently on the market. The standard conveyor drive FEED SYSTEMS ® ORIENTAINER ® This pre-engineered conveyor less steel locking nut. These are

Stainless steel bolts are stan- consists of a permanent magnet 3 rail system will gently transfer also sold separately for existing

dard. 90V-DC motor of overcapacity 90° TURN 7 containers, etc., from one con- equipment.

1 Modular with a 120V-AC solid-state vari- 2 veyor to another in a smooth 15 Back-up Sensor

automated fashion. This unique

able speed controller in a NEMA

Conveying Systems 12 control box complete with 9 design allows for adjustment of

CONVEYS-ALL conveying sys- on-off switch. A fixed speed AC 15 widths without change parts. Conveyor anti-back-up sensors.

tems are designed to give flexi- drive is also available at no extra

bility of use. Each conveyor cost. The modular drive units 8 13 12 Electrical Equipment System Components

component can be mixed, easily connect to either the 45° TURN 6

matched, reconfigured or curved or straight run conveyor Standard electric is 220V, 1 PH,

added-on when needed. These sections. 60/50 Hz or 110V, 1 PH, 60/50 • Rotary bottle and container

modular cost-effective designs 3 1 Hz (NEMA 12). For hazardous feeder tables.

can be easily modified to keep 3 Table-Top Conveyor locations requiring “explosion • Automatic bottle and con-

pace with all your future needs. Chains proofing”, an all air drive and tainer feeders.

controls are utilized. Extra long • Rotary surge tables.

Low capital costs— Various styles available: TABLE TOP 3 12 lengths (over 20 ft.) are provided • Rotary accumulating tables.

3-Year Guarantee A) Acetal thermoplastic CONVEYOR CHAINS 11 with a heavy duty drive. Other • Dust covers over conveyors

with stainless steel pins. voltages are available. to protect open packages

CONVEYS-ALL conveyors are (std). 5 6 Custom prior to being closed.

competitively priced and feature B) Stainless steel top with • Bulk parts elevators and

high quality materials and com- stainless steel pins. 4 7 5 Engineering Services feeders.

ponents, along with rugged con- C) Polypropylene. • Missing cap and foil detetors.

struction, reliability and D) Polyvinyl Chloride (PVC). Our design engineers use CAD • Bottle and part counters/

longevity of operation. All con- Available widths are: 10 12 (computer aided design) systems totalizers and rate meters.

veyor systems are guaranteed 3-1/4 inch, 4-1/2 inch, 6 SINGLE RAIL 4 to lay out designs and calculate • Bottle carriers

for 3 years—the longest in the inch, 7 inch, 10 inch or 12 the best conveyor system for

™

industry. inch widths. DOUBLE RAILS 10 your requirements. Our staff will Ask for more information and

be happy to assist you — please literature on our complete line

4 Conveyor Support call today. (See back page for of bottling machinery (including

48 Hour Shipping typical design layouts). unscramblers,cleaners,fillers,

Available* Stands 14

8 cappers,torque meters, accumu-

“Off-the-shelf ” conveyor com- Stainless steel welded supports 11 13 Sanitary lators, etc.).

ponents can be shipped within are bolted directly to the con- ™ Design

48-hours upon receipt of order. veyor. They come complete with Conveyors

Depending upon the conveyor stainless steel elevating/leveling 8

size, these modular pre-engi- screws with swivel design, glass-

neered conveyors come either filled nylon floor pads. The con- The Proven Standard ® . . . Since 1941 1 Standard Design 13 Sanitary Design A raised/elevated

fully assembled or partially veyor supports eliminate con- Conveyor Frame chain design allows

assembled (fully assembled and veyor sag, vibration and move- for easy cleaning

ment while allowing for easy making it ideal for

*See quote for further details. side channels for optimal safety (total conveyor length) to 38 feet. polyethylene. Single and/or double sold separately for existing convey- inch radius are available. pharmaceutical

cleaning under the conveyor. and cleanliness. Standard conveyor lengths are in rails are available. ors. These pre-engineered

™

multiples of 7-1/2 feet. Custom curved sections can easily and food applica-

5 Conveyor End 6 Straight Conveyor lengths are available to the closest 8 Conveyor Rail Posts 9 be inserted anywhere tions. A space is

Covers/Guarding Module Sections 1/4 inch for your exact needs. Curved Conveyor between the modular CON- provided between

Modular Sections

Glass-filled nylon posts are provid- VEYS-ALL system sections the conveyor table

Stainless steel adjustable end The standard conveyor frame is 7 Conveyor Guide Rails ed in either a 3 position height to meet your requirements. top chain and the

covers eliminate pinch points. constructed of stainless steel and adjustment version with stainless Modular 90 degree and 45 degree Each curved modular sec- stainless steel con-

They are removable for bolting is suitable for 3-1/4 inch or 4-1/2 Fully adjustable conveyor rails steel fully adjustable horizontal turns are available with stainless tion comes with provisions veyor frame for

together of additional conveyor inch chain. (Optional widths go up provide ultra-stability and are posts or an exclusive patented infi- steel sides and include all the fea- for a stainless steel floor easy cleaning. The

lengths. All drive chains are to 12 inches). The conveyor available in stainless steel, alu- nitely adjustable horizontal and tures of the standard straight con- support stand. CONVEYS-ALL

housed within the stainless steel lengths are available from 3 feet minum or covered with UHMW vertical post system. These are also veyor. Both an 18 inch and a 24 sanitary conveyor