Page 2205 - Flipbook_SolidDesignSoutheast2020

P. 2205

packaging automation systems

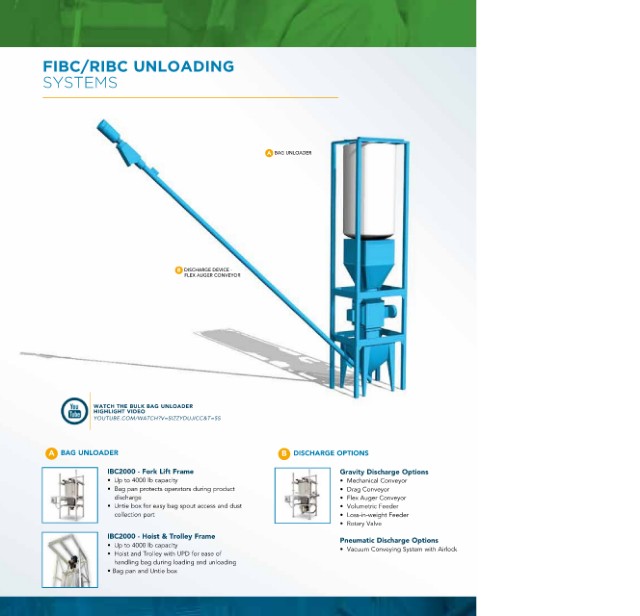

FIBC/RIBC FILLING FIBC/RIBC UNLOADING

SYSTEMS SYSTEMS

A BAG FILLER

A BAG UNLOADER

B PALLET DISPENSER

B DISCHARGE DEVICE -

FLEX AUGER CONVEYOR

C EXIT CONVEYOR

WATCH AN AUTOMATED BULK BAG

FILLING LINE IN ACTION:

YOUTUBE.COM/WATCH?V=_TG5DHLQWFQ&T=5S

A BULK FILLER

IBC3000 C EXIT CONVEYOR

• Fill up to 3000 lb bags/containers WATCH THE BULK BAG UNLOADER

• Adjustable Bag Clamps for Various Bag Sizes Roller Conveyors HIGHLIGHT VIDEO

• Double wall/inflatable spout with neck seal • Transfer pallets with bottom boards in YOUTUBE.COM/WATCH?V=SIZZYDUJICC&T=5S

for dust control

parallel with direction of travel

3 Chain Conveyors

• Economical option, easy for operators to

IBC4000 stand on while hanging bag A BAG UNLOADER B DISCHARGE OPTIONS

• Actuated knife gate for bulk and dribble filling Slat Conveyors

• Integrated load cell weigh system for increased • Used when no pallet is present, can also IBC2000 - Fork Lift Frame Gravity Discharge Options

accuracy • Up to 4000 lb capacity • Mechanical Conveyor

• Double wall/inflatable spout with neck seal for dust be a source for operators to stand on • Bag pan protects operators during product • Drag Conveyor

while hanging bag

control discharge • Flex Auger Conveyor

• Untie box for easy bag spout access and dust • Volumetric Feeder

collection port • Loss-in-weight Feeder

D BOX DENESTER

B PALLET DISPENSER • Rotary Valve

TRD2000 ROBOTIC DENESTER

PALLET DISPENSER • Prepare 3 nested boxes for filling IBC2000 - Hoist & Trolley Frame Pneumatic Discharge Options

• Store up to 17 empty pallets • Automatically indexes box to fill station • Up to 4000 lb capacity • Vacuum Conveying System with Airlock

• Automatically indexes empty pallet for • 120 cycles times per hour • Hoist and Trolley with UPD for ease of

placement of slip sheet and or container prior handling bag during loading and unloading

to filling. • Bag pan and Untie box