Page 2305 - Flipbook_SolidDesignSoutheast2020

P. 2305

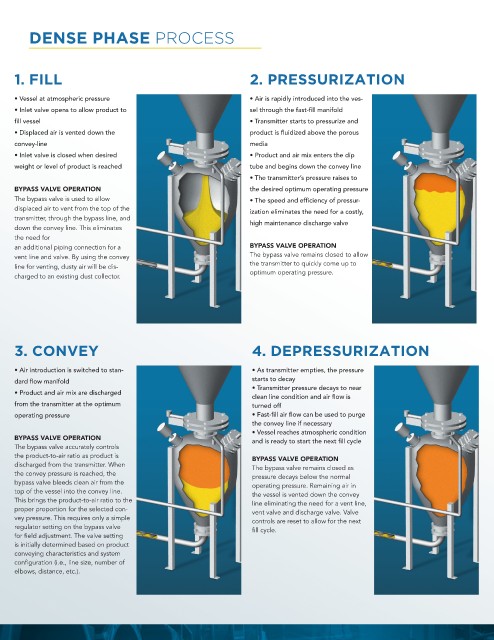

DENSE PHASE PROCESS

1. FILL 2. PRESSURIZATION

• Vessel at atmospheric pressure • Air is rapidly introduced into the ves-

• Inlet valve opens to allow product to sel through the fast-fill manifold

fill vessel • Transmitter starts to pressurize and

• Displaced air is vented down the product is fluidized above the porous

convey-line media

• Inlet valve is closed when desired • Product and air mix enters the dip

weight or level of product is reached tube and begins down the convey line

• The transmitter’s pressure raises to

BYPASS VALVE OPERATION the desired optimum operating pressure

The bypass valve is used to allow • The speed and efficiency of pressur-

displaced air to vent from the top of the ization eliminates the need for a costly,

transmitter, through the bypass line, and

down the convey line. This eliminates high maintenance discharge valve

the need for

an additional piping connection for a BYPASS VALVE OPERATION

vent line and valve. By using the convey The bypass valve remains closed to allow

line for venting, dusty air will be dis- the transmitter to quickly come up to

charged to an existing dust collector. optimum operating pressure.

3. CONVEY 4. DEPRESSURIZATION

• Air introduction is switched to stan- • As transmitter empties, the pressure

dard flow manifold starts to decay

• Transmitter pressure decays to near

• Product and air mix are discharged

clean line condition and air flow is

from the transmitter at the optimum turned off

operating pressure • Fast-fill air flow can be used to purge

the convey line if necessary

• Vessel reaches atmospheric condition

BYPASS VALVE OPERATION and is ready to start the next fill cycle

The bypass valve accurately controls

the product-to-air ratio as product is BYPASS VALVE OPERATION

discharged from the transmitter. When The bypass valve remains closed as

the convey pressure is reached, the pressure decays below the normal

bypass valve bleeds clean air from the operating pressure. Remaining air in

top of the vessel into the convey line. the vessel is vented down the convey

This brings the product-to-air ratio to the line eliminating the need for a vent line,

proper proportion for the selected con- vent valve and discharge valve. Valve

vey pressure. This requires only a simple controls are reset to allow for the next

regulator setting on the bypass valve fill cycle.

for field adjustment. The valve setting

is initially determined based on product

conveying characteristics and system

configuration (i.e., line size, number of

elbows, distance, etc.).