Page 2306 - Flipbook_SolidDesignSoutheast2020

P. 2306

DENSE PHASE APPLICATIONS

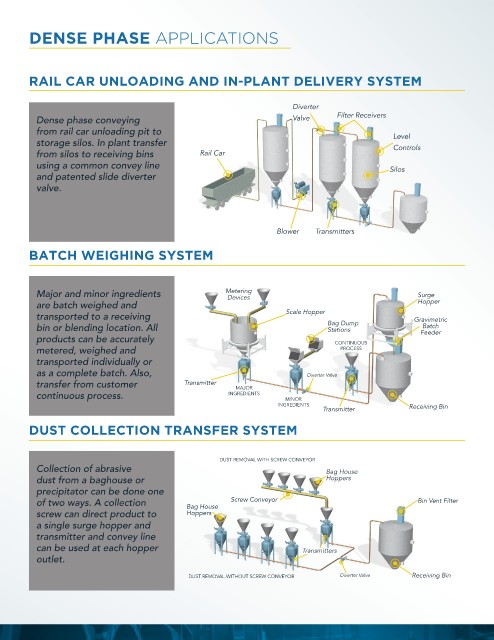

RAIL CAR UNLOADING AND IN-PLANT DELIVERY SYSTEM

Diverter

Dense phase conveying Valve Filter Receivers

from rail car unloading pit to Level

storage silos. In plant transfer Controls

from silos to receiving bins Rail Car

using a common convey line Silos

and patented slide diverter

valve.

Blower Transmitters

BATCH WEIGHING SYSTEM

Major and minor ingredients Metering Surge

Devices

are batch weighed and Hopper

transported to a receiving Scale Hopper Gravimetric

bin or blending location. All Bag Dump Feeder

Batch

Stations

products can be accurately CONTINUOUS

metered, weighed and PROCESS

transported individually or

as a complete batch. Also, Diverter Valve

transfer from customer Transmitter MAJOR

continuous process. INGREDIENTS MINOR

INGREDIENTS Receiving Bin

Transmitter

DUST COLLECTION TRANSFER SYSTEM

DUST REMOVAL WITH SCREW CONVEYOR

Collection of abrasive Bag House

dust from a baghouse or Hoppers

precipitator can be done one

of two ways. A collection Bag House Screw Conveyor Bin Vent Filter

screw can direct product to Hoppers

a single surge hopper and

transmitter and convey line

can be used at each hopper Transmitters

outlet.

DUST REMOVAL WITHOUT SCREW CONVEYOR Diverter Valve Receiving Bin