Page 2395 - Flipbook_SolidDesignSoutheast2020

P. 2395

packaging automation systems

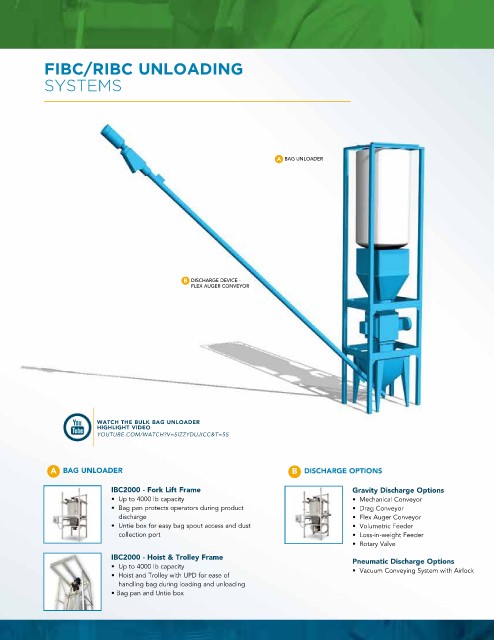

FIBC/RIBC UNLOADING

SYSTEMS

A BAG UNLOADER

B DISCHARGE DEVICE -

FLEX AUGER CONVEYOR

WATCH THE BULK BAG UNLOADER

HIGHLIGHT VIDEO

YOUTUBE.COM/WATCH?V=SIZZYDUJICC&T=5S

A BAG UNLOADER B DISCHARGE OPTIONS

IBC2000 - Fork Lift Frame Gravity Discharge Options

• Up to 4000 lb capacity • Mechanical Conveyor

• Bag pan protects operators during product • Drag Conveyor

discharge • Flex Auger Conveyor

• Untie box for easy bag spout access and dust • Volumetric Feeder

collection port • Loss-in-weight Feeder

• Rotary Valve

TRD2000 ROBOTIC DENESTER IBC2000 - Hoist & Trolley Frame

• Prepare 3 nested boxes for filling • Up to 4000 lb capacity Pneumatic Discharge Options

• Automatically indexes box to fill station • Hoist and Trolley with UPD for ease of • Vacuum Conveying System with Airlock

• 120 cycle times per hour handling bag during loading and unloading

• Bag pan and Untie box