Page 2772 - Flipbook_SolidDesignSoutheast2020

P. 2772

HAMMERHEAD HAMMER MILLS

™

Reduce a broad range of materials into particle sizes from coarse to fine

—efficiently, at high rates

Munson’s HammerHead™ Hammer The shaft assembly, which consists

Mills reduce an exceptionally wide of a primary shaft, multiple discs Mill case and hinged

range of friable, non-friable and and six hammer mounting bars, access door—both

fibrous materials into particle sizes are driven at 1,800 to 3,600 RPM constructed of welded

from coarsepieces down to 200 by a high horsepower motor. heavy-gauge carbon

mesh, determined by friability of steel and machined

the material. The proprietary hardened hammers flanges—are secured

can be reversed end-to-end and by an equally robust

The high-shear/low-resistance side-to-side, allowing all four latch assembly.

cutting action of the hammer tips cutting edges to be utilized before

rotating at speeds up to 270 MPH, being replaced. A removable pin,

together with the rotational inertia recessed within a hardened steel

of the heavy-weight rotor assembly, guard, allows rapid removal

reduces higher volumes of of the secondary shafts, hammers

materials and yields greater output and spacers for servicing.

per horsepower/kilowatt than with The unit is configured with a large sealed flange-block bearings

many other types of mills. In addition, all corners of the safety-interlocked door, providing mounted on a heavy-gauge

hammers are stepped as standard, rapid, unobstructed access to the fabricated and machined housing,

Centrifugal force causes pivoting offering three-times the cutting mill case interior. providing vibration-free operation.

hammers to stand at 90° to the edges of square-cut hammer tips

rotating shaft, striking material in for greater efficiency. The upper cylindrical breaker plates Carbon steel or stainless steel

mid-air and smashing it at high speed and lower bed screens slide within construction in a range of finishes

against hardened breaker plate ridges For general grinding, standard precision-machined channels, and is offered to satisfy virtually any

until particles are sufficiently reduced equipment consists of alternating are held captive by the unit’s door industrial requirement.

to pass through a bed screen. heavy and light hammers. when closed, providing secure,

However, the type, number and dust-tight operation as well as IMPORTANT NOTE: Since all

Particle sizes are determined by the arrangement of hammers can rapid removal of internals. hammer mills are limited in terms

friability of the material and the size be varied readily to optimize of particle size control and

of bedscreen perforations which range performance according to As standard, cylindrical breaker prevention of fines, Munson

from 1/32 to 3 inch (0.8 to 76 mm). material characteristics. plates encircle the upper half of the Centrifugal Impact Mills (Pin

mill chamber, while bed screens Mills) and Munson SCC™ Screen

encircle the lower half. However, Classifying Cutters may alternately

when greater throughput of easily- be considered.

reduced materials is desired, a 90º

section of breaker plate located

below the hinged top section of the

mill case can be substituted with

a 90º cylindrical section of bed

screen, increasing total screen area

to 270º.

Material is fed through the infeed

hopper at the top of the mill,

while on-size particles exit through

a lower flanged outlet, and are

typically removed by dilute-phase

vacuum collection, or are gravity

fed into a downstream process.

The shaft assembly consists of

The heavy-gauge housing provides a primary shaft of alloy steel,

the stiffness required to maintain multiple shaft discs and six quick-

precise alignment, and withstand disconnect hammer mounting bars

the extreme impact and high with “stepped-tip” hammers shown

loads of the most demanding standing at 90° to the rotating shaft

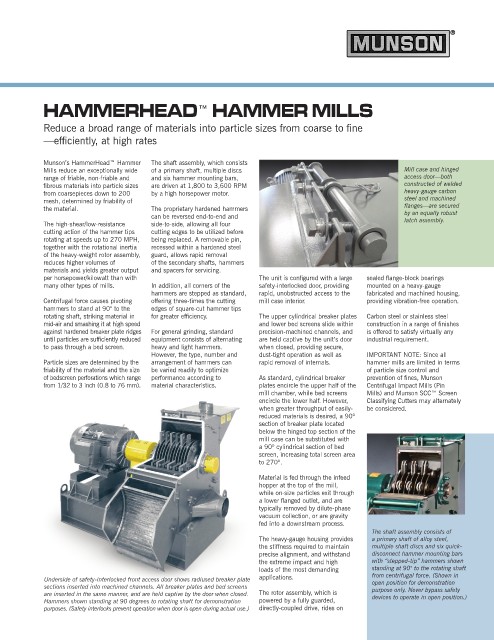

Underside of safety-interlocked front access door shows radiused breaker plate applications. from centrifugal force. (Shown in

open position for demonstration

sections inserted into machined channels. All breaker plates and bed screens purpose only. Never bypass safety

are inserted in the same manner, and are held captive by the door when closed. The rotor assembly, which is devices to operate in open position.)

Hammers shown standing at 90 degrees to rotating shaft for demonstration powered by a fully guarded,

purposes. (Safety interlocks prevent operation when door is open during actual use.) directly-coupled drive, rides on