Page 2773 - Flipbook_SolidDesignSoutheast2020

P. 2773

FEATURES TYPICAL OPTIONS

n Large, obstruction-free product n Lower transition for pneumatic APPLICATIONS n Stainless steel construction

feed opening removal of reduced materials n Animal feed, biomass, corn to industrial standards

n Peripheral hammer velocity from n Hinged mill case door provides n Batteries n Change-out of 90º breaker

3,600 to 24,000 ft/min (1,100 unobstructed interior access for n Bulk spices, herbs, food plate section with 90º bed

to 7,300 m/min) together with rapid inspection and changing products screen section, increasing total

hard-faced breaker plates and of breaker plates, screens and n Carpet and carpet grindings cylindrical bed screen area

perforated bed screen, reduces hammers to 270º of mill chamber for

wide range of material types and n Machined mating surfaces of n Ceramics, cement, lime maximum output

sizes at high rates door and mill case provide n Chemical products in bulk n Bar-type “bed screens”

n Greater output per horsepower/ dust-tight operation and solid form n Square tipped hammers

kilowatt than many other types n Directly-coupled drive n Coal, slag

of mills n Glass bottles, cullet, syringes n Pre-crusher installed ahead

of the hammer mill for initial

n Hardened steel hammers with n Welded heavy-plate carbon steel n Grains, seeds and shells reduction of large pieces and/or

mill case maintains precision

“stepped ends” offer three-times alignment of dynamically- uniform feeding of small pieces

the cutting edges of square-end balanced rotor assembly despite n Filings, turnings, shavings

hammers extreme impact and high loads n Mining materials n Controls including variable

speed drives

n Four-way reversible design of demanding applications n Paper/newspaper

allows all stepped hammer n Horsepower range from n Plastic parts, housings, n Rotational sensors for feedback

corners to be utilized prior 50-250 HP reinforced composites to automated systems

to replacing n Roof shingles n Legs to raise discharge height

n Radiused bed screens with n Rubber-steel-cord separation n Air purge seal assembly with

perforations from 1/32 to 3 in. external pillow block bearings

(0.8 to 76 mm) n Storage media, hard drives, for extremely demanding

PCBs, phones/electronics applications

of all types

I

n Sugarcane n ntegral fan and blower assembly

n Wood bark, scrap, chips, n Special configurations

shavings, particle/fiber board,

hogged scrap

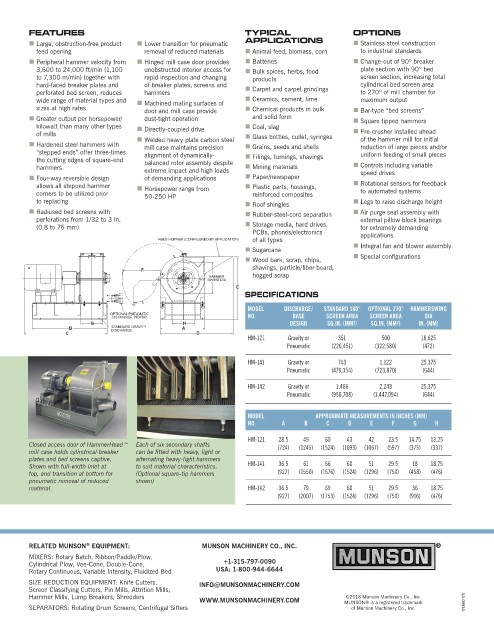

SPECIFICATIONS

MODEL DISCHARGE/ STANDARD 180° OPTIONAL 270° HAMMERSWING

NO. BASE SCREEN AREA SCREEN AREA DIA

DESIGN SQ.IN. (MM 2 ) SQ.IN. (MM 2 ) IN. (MM)

HM-121 Gravity or 351 500 18.625

Pneumatic (226,451) (322,580) (472)

HM-141 Gravity or 743 1,122 25.375

Pneumatic (479,354) (723,870) (644)

HM-142 Gravity or 1,486 2,243 25.375

Pneumatic (958,708) (1,447,094) (644)

MODEL APPROXIMATE MEASUREMENTS IN INCHES (MM)

NO. A B C D E F G H

HM-121 28.5 49 60 43 42 23.5 14.75 13.25

Closed access door of HammerHead™ Each of six secondary shafts (724) (1245) (1524) (1093) (1067) (597) (375) (337)

mill case holds cylindrical breaker can be fitted with heavy, light or

plates and bed screens captive. alternating heavy-light hammers

Shown with full-width inlet at to suit material characteristics. HM-141 36.5 61 66 60 51 29.5 18 18.75

top, and transition at bottom for (Optional square-tip hammers (927) (1550) (1676) (1524) (1296) (750) (458) (476)

pneumatic removal of reduced shown)

material. HM-142 36.5 79 69 60 51 29.5 36 18.75

(927) (2007) (1753) (1524) (1296) (750) (916) (476)

®

RELATED MUNSON EQUIPMENT: MUNSON MACHINERY CO., INC.

MIXERS: Rotary Batch, Ribbon/Paddle/Plow,

Cylindrical Plow, Vee-Cone, Double-Cone, +1-315-797-0090

Rotary Continuous, Variable Intensity, Fluidized Bed USA: 1-800-944-6644

SIZE REDUCTION EQUIPMENT: Knife Cutters, INFO@MUNSONMACHINERY.COM

Screen Classifying Cutters, Pin Mills, Attrition Mills,

Hammer Mills, Lump Breakers, Shredders ©2018 Munson Machinery Co., Inc.

WWW.MUNSONMACHINERY.COM MUNSON® is a registered trademark AA-0993A

SEPARATORS: Rotating Drum Screens, Centrifugal Sifters of Munson Machinery Co., Inc.