Page 2768 - Flipbook_SolidDesignSoutheast2020

P. 2768

DE-CLUMPER LUMP BREAKERS

™

Reduce agglomerates and compacted materials to original particle sizes

and flowability for downstream processes

n Compact, low-profile design n Models with 1 to 4 rotors

allows inline placement in sizes from 12 x 12 to

between upstream and 48 x 48 in. (30.5 x 30.5

downstream equipment to 121.9 x 121.9 cm)

n Robust design and n Single 3 hp (2.2 kw) drives

construction makes it suitable to 20+ hp (14.9+ kw) dual

for use as a light duty crusher redundant drives

as well as an ultra-heavy n Chain and sprocket drives

duty lump breaker handle high loads and offer

n Available in stand-alone superior durability

configurations with hopper n Operates at low RPM for

and stand gentle handling with little

n External lubrication access or no heat generation

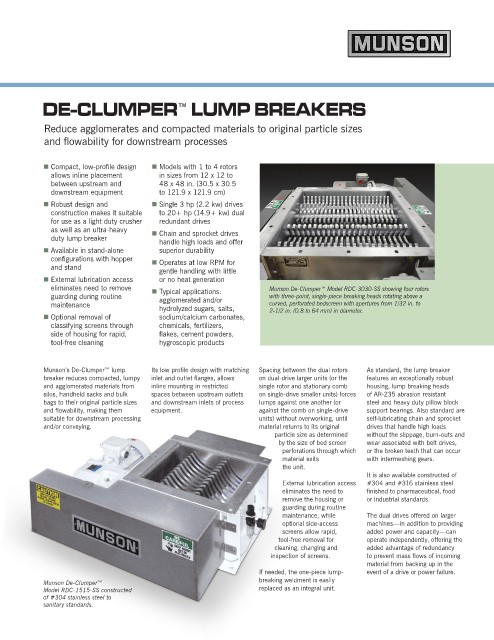

eliminates need to remove n Typical applications: Munson De-Clumper™ Model RDC-3030-SS showing four rotors

guarding during routine agglomerated and/or with three-point, single-piece breaking heads rotating above a

maintenance curved, perforated bedscreen with apertures from 1/32 in. to

hydrolyzed sugars, salts, 2-1/2 in. (0.8 to 64 mm) in diameter.

n Optional removal of sodium/calcium carbonates,

classifying screens through chemicals, fertilizers,

side of housing for rapid, flakes, cement powders,

tool-free cleaning hygroscopic products

Munson’s De-Clumper™ lump Its low profile design with matching Spacing between the dual rotors As standard, the lump breaker

breaker reduces compacted, lumpy inlet and outlet flanges, allows on dual-drive larger units (or the features an exceptionally robust

and agglomerated materials from inline mounting in restricted single rotor and stationary comb housing, lump breaking heads

silos, handheld sacks and bulk spaces between upstream outlets on single-drive smaller units) forces of AR-235 abrasion resistant

bags to their original particle sizes and downstream inlets of process lumps against one another (or steel and heavy duty pillow block

and flowability, making them equipment. against the comb on single-drive support bearings. Also standard are

suitable for downstream processing units) without overworking, until self-lubricating chain and sprocket

and/or conveying. material returns to its original drives that handle high loads

particle size as determined without the slippage, burn-outs and

by the size of bed screen wear associated with belt drives,

perforations through which or the broken teeth that can occur

material exits with intermeshing gears.

the unit.

It is also available constructed of

External lubrication access #304 and #316 stainless steel

eliminates the need to finished to pharmaceutical, food

remove the housing or or industrial standards.

guarding during routine

maintenance, while The dual drives offered on larger

optional side-access machines—in addition to providing

screens allow rapid, added power and capacity—can

tool-free removal for operate independently, offering the

cleaning, changing and added advantage of redundancy

inspection of screens. to prevent mass flows of incoming

material from backing up in the

If needed, the one-piece lump- event of a drive or power failure.

Munson De-Clumper™ breaking weldment is easily

Model RDC-1515-SS constructed replaced as an integral unit.

of #304 stainless steel to

sanitary standards.