Page 2778 - Flipbook_SolidDesignSoutheast2020

P. 2778

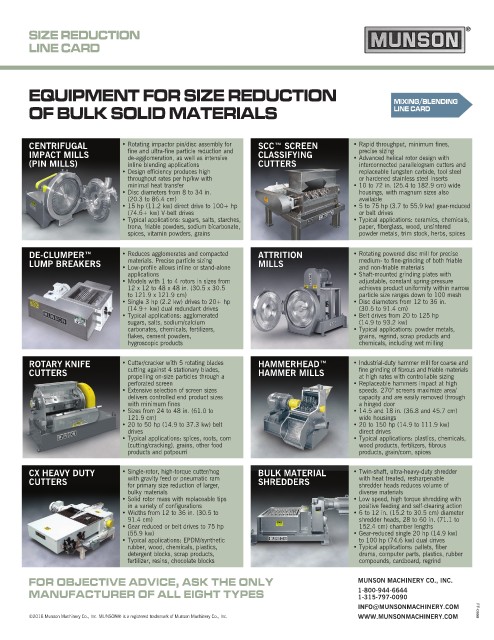

SIZE REDUCTION

LINE CARD

EQUIPMENT FOR SIZE REDUCTION MIXING/BLENDING

OF BULK SOLID MATERIALS LINE CARD

Centrifugal • Rotating impactor pin/disc assembly for sCC™ sCreen • Rapid throughput, minimum fines,

precise sizing

impaCt mills fine and ultra-fine particle reduction and ClassifYing • Advanced helical rotor design with

de-agglomeration, as well as intensive

(pin mills) inline blending applications Cutters interconnected parallelogram cutters and

• Design efficiency produces high replaceable tungsten carbide, tool steel

throughput rates per hp/kw with or hardened stainless steel inserts

minimal heat transfer • 10 to 72 in. (25.4 to 182.9 cm) wide

• Disc diameters from 8 to 34 in. housings, with magnum sizes also

(20.3 to 86.4 cm) available

• 15 hp (11.2 kw) direct drive to 100+ hp • 5 to 75 hp (3.7 to 55.9 kw) gear-reduced

(74.6+ kw) V-belt drives or belt drives

• Typical applications: sugars, salts, starches, • Typical applications: ceramics, chemicals,

trona, friable powders, sodium bicarbonate, paper, fiberglass, wood, unsintered

spices, vitamin powders, grains powder metals, trim stock, herbs, spices

De-Clumper™ • Reduces agglomerates and compacted attritiOn • Rotating powered disc mill for precise

materials. Precise particle sizing

lump BreaKers • Low-profile allows inline or stand-alone mills medium- to fine-grinding of both friable

and non-friable materials

applications • Shaft-mounted grinding plates with

• Models with 1 to 4 rotors in sizes from adjustable, constant spring-pressure

12 x 12 to 48 x 48 in. (30.5 x 30.5 achieves product uniformity within narrow

to 121.9 x 121.9 cm) particle size ranges down to 100 mesh

• Single 3 hp (2.2 kw) drives to 20+ hp • Disc diameters from 12 to 36 in.

(14.9+ kw) dual redundant drives (30.5 to 91.4 cm)

• Typical applications: agglomerated • Belt drives from 20 to 125 hp

sugars, salts, sodium/calcium (14.9 to 93.2 kw)

carbonates, chemicals, fertilizers, • Typical applications: powder metals,

flakes, cement powders, grains, regrind, scrap products and

hygroscopic products chemicals, including wet milling

rOtarY Knife • Cutter/cracker with 5 rotating blades HammerHeaD™ • Industrial-duty hammer mill for coarse and

Cutters cutting against 4 stationary blades, Hammer mills fine grinding of fibrous and friable materials

propelling on-size particles through a

at high rates with controllable sizing

perforated screen • Replaceable hammers impact at high

• Extensive selection of screen sizes speeds. 270° screens maximize area/

delivers controlled end product sizes capacity and are easily removed through

with minimum fines a hinged door

• Sizes from 24 to 48 in. (61.0 to • 14.5 and 18 in. (36.8 and 45.7 cm)

121.9 cm) wide housings

• 20 to 50 hp (14.9 to 37.3 kw) belt • 20 to 150 hp (14.9 to 111.9 kw)

drives direct drives

• Typical applications: spices, roots, corn • Typical applications: plastics, chemicals,

(cutting/cracking), grains, other food wood products, fertilizers, fibrous

products and potpourri products, grain/corn, spices

CX HeavY DutY • Single-rotor, high-torque cutter/hog BulK material • Twin-shaft, ultra-heavy-duty shredder

Cutters with gravity feed or pneumatic ram sHreDDers with heat treated, resharpenable

shredder heads reduces volume of

for primary size reduction of larger,

bulky materials diverse materials

• Solid rotor mass with replaceable tips • Low speed, high torque shredding with

in a variety of configurations positive feeding and self-clearing action

• Widths from 12 to 36 in. (30.5 to • 6 to 12 in. (15.2 to 30.5 cm) diameter

91.4 cm) shredder heads, 28 to 60 in. (71.1 to

• Gear reduced or belt drives to 75 hp 152.4 cm) chamber lengths

(55.9 kw) • Gear-reduced single 20 hp (14.9 kw)

• Typical applications: EPDM/synthetic to 100 hp (74.6 kw) dual drives

rubber, wood, chemicals, plastics, • Typical applications: pallets, fiber

detergent blocks, scrap products, drums, computer parts, plastics, rubber

fertilizer, resins, chocolate blocks compounds, cardboard, regrind

FOR OBjECTIvE ADvICE, ASK ThE ONLy munsOn maCHinerY CO., inC.

MANUFACTURER OF ALL EIGhT TyPES 1-800-944-6644

1-315-797-0090

infO@munsOnmaCHinerY.COm FF-0998

©2018 Munson Machinery Co., Inc. MUNSON® is a registered trademark of Munson Machinery Co., Inc. www.munsOnmaCHinerY.COm

FF-0998_LineCard_20180105.indd 1 1/5/18 8:58 AM