Page 2985 - Flipbook_SolidDesignSoutheast2020

P. 2985

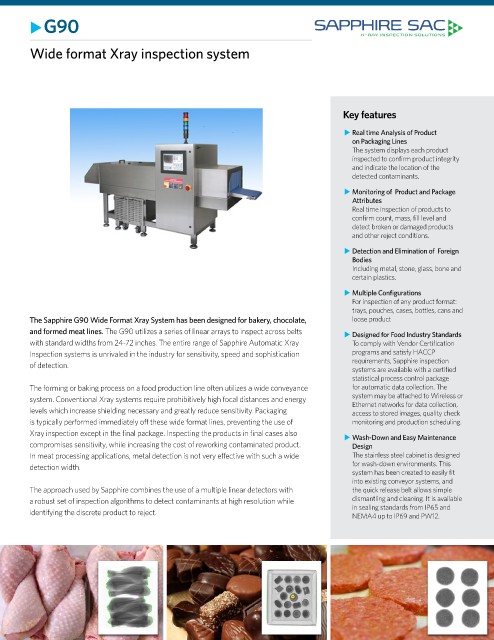

X XG90

Wide format Xray inspection system

Key features

R

X Xeal time Analysis of Product

on Packaging Lines

The system displays each product

inspected to confirm product integrity

and indicate the location of the

detected contaminants.

X XMonitoring of Product and Package

Attributes

Real time inspection of products to

confirm count, mass, fill level and

detect broken or damaged products

and other reject conditions.

X XDetection and Elimination of Foreign

Bodies

Including metal, stone, glass, bone and

certain plastics.

X XMultiple Configurations

For inspection of any product format:

trays, pouches, cases, bottles, cans and

The Sapphire G90 Wide Format Xray System has been designed for bakery, chocolate, loose product

and formed meat lines. The G90 utilizes a series of linear arrays to inspect across belts X XDesigned for Food Industry Standards

with standard widths from 24-72 inches. The entire range of Sapphire Automatic Xray To comply with Vendor Certification

Inspection systems is unrivaled in the industry for sensitivity, speed and sophistication programs and satisfy HACCP

of detection. requirements, Sapphire inspection

systems are available with a certified

statistical process control package

The forming or baking process on a food production line often utilizes a wide conveyance for automatic data collection. The

system. Conventional Xray systems require prohibitively high focal distances and energy system may be attached to Wireless or

Ethernet networks for data collection,

levels which increase shielding necessary and greatly reduce sensitivity. Packaging access to stored images, quality check

is typically performed immediately off these wide format lines, preventing the use of monitoring and production scheduling.

Xray inspection except in the final package. Inspecting the products in final cases also X XWash-Down and Easy Maintenance

compromises sensitivity, while increasing the cost of reworking contaminated product. Design

In meat processing applications, metal detection is not very effective with such a wide The stainless steel cabinet is designed

detection width. for wash-down environments. This

system has been created to easily fit

into existing conveyor systems, and

The approach used by Sapphire combines the use of a multiple linear detectors with the quick release belt allows simple

a robust set of inspection algorithms to detect contaminants at high resolution while dismantling and cleaning. It is available

identifying the discrete product to reject. in sealing standards from IP65 and

NEMA4 up to IP69 and PW12.