Page 20 - MILLING-TOOLS-yg1

P. 20

CASE STUDY CASE STUDY

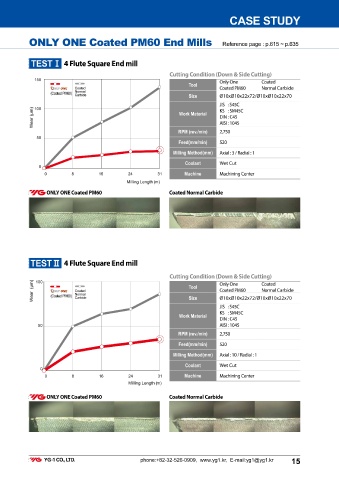

ALU-POWER HPC End mills Reference page : p.463 ~ p.475 ONLY ONE Coated PM60 End Mills Reference page : p.615 ~ p.635

Slotting Application 4 Flute Square End mill

Cutting Condition (Slotting)

Ø1/2(R.090) 3 Flute Corner radius End Mill, Alu-Power HPC Tool Ø1/2(R.090) x Ø1/2 x 1-1/4 x 3-1/2 150 Cutting Condition (Down & Side Cutting)

Work Material AL7075 Tool Only One Coated

115% R.P.M (rev./min.) 12,224 (Coated PM60) Coated Coated PM60 Normal Carbide

Normal

Feed (mm/min.) 5,588 Carbide Size Ø10xØ10x22x72/Ø10xØ10x22x70

ALU-POWER HPC Cutting Depth (mm) 12.7 (Axial) 100 JIS : S45C

110% Coolant Wet Cut (9% emulsion) Work Material KS : SM45C

Overhang (mm) 48 Wear (μm) DIN : C45

AISI : 1045

Milling Method Slotting

105% Machine Machining Center RPM (rev./min) 2,750

50

Total Milling Length : 38m Feed(mm/min) 520

100% ALU-POWER HPC Milling Method(mm) Axial : 3 / Radial : 1

Competitor A Coolant

0 Wet Cut

95% 0 8 16 24 31 Machine Machining Center

Competitor A

Milling Length : 28.6m Milling Length : 28.6m Milling Length (m)

Wear land : 16.617 ㎛ Wear land : 12.896 ㎛

90% ONLY ONE Coated PM60 Coated Normal Carbide

Pocketing Application

Cutting Condition (Pocketing)

Ø1/2(R.090) 3 Flute Corner radius End Mill, Alu-Power HPC Tool Ø1/2(R.090) x Ø1/2 x 1-1/4 x 3-1/2

Work Material AL7075

130% R.P.M (rev./min.) 12,224

Feed (mm/min.) 5,588

Cutting Depth (mm) 12.7 (Axial) / 12.2 (Radial)

120% Coolant Wet Cut (9% emulsion) 4 Flute Square End mill

Overhang (mm) 48 Cutting Condition (Down & Side Cutting)

ALU-POWER HPC Milling Method Pocketing 100

110% Machine Machining Center Coated Tool Only One Coated

Coated PM60

Normal Carbide

Total Milling Length : 38m Wear (μm) (Coated PM60) Normal Size Ø10xØ10x22x72/Ø10xØ10x22x70

Carbide

100% ALU-POWER HPC JIS : S45C

Competitor A KS : SM45C

Work Material

DIN : C45

90% 50 AISI : 1045

Competitor A

Milling Length : 38m Milling Length : 38m RPM (rev./min) 2,750

Wear land : 15.385 ㎛ Wear land : 12.896 ㎛ Feed(mm/min) 520

80%

Milling Method(mm) Axial : 10 / Radial : 1

D 2

Coolant Wet Cut

0

a e

0 8 16 24 31 Machine Machining Center

Radial Milling Length (m)

infeed

y

z x ONLY ONE Coated PM60 Coated Normal Carbide

rad m

rad vt

D c

Groove width

In trochoidal milling applications, Peel milling applications Outstanding chip evacuation

the cutter follows a spiral path by moving benefit from ALU-POWER HPC's super through deep gullet design coupled

radially as it rotates providing faster sharp high-speed milling ability. with high speed milling leaves

machining times, lower tooling costs and a well-defined clean cutter path.

reduced loads on machine components.

14 phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr phone:+82-32-526-0909, www.yg1.kr, E-mail:yg1@yg1.kr 15