Page 174 - FAT 105 4.17 MOODLE

P. 174

you might want yours anywhere from 30” to

Workbenches 35”. Above all, the bench must be sturdy and

firm. You cannot do your best work if the bench

moves every time you take a file stroke or tap

When beginning gunsmiths start to think a drift pin out of its hole. Therefore, the ideal

of graduating from the toolbox/repair kit workbench should be amply reinforced, and the

stage to a full-fledged workshop, their first legs and top should be made of heavy timber.

thoughts should turn to a suitable workbench. In addition to the main workbench, it is nice to

Unfortunately, there are not very many commer-

have an auxiliary bench for special projects. One

cial workbenches to choose from and those that such bench is shown in Figure 4. In small shops,

are available are usually expensive. Therefore,

this bench will also suffice as a main bench, and

most gunsmiths like to build their own. although the legs are constructed of 2 x 4’s the

In general, a workbench should be 30” wide and plywood bracing makes it very sturdy.

from 5’ to 12’ long. However, do not skimp on

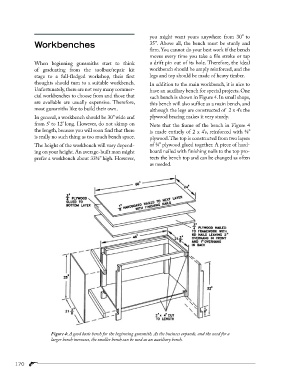

Note that the frame of the bench in Figure 4

the length, because you will soon find that there is made entirely of 2 x 4’s, reinforced with 3/8”

is really no such thing as too much bench space.

plywood. The top is constructed from two layers

The height of the workbench will vary depend- of 3/4” plywood glued together. A piece of hard-

ing on your height. An average-built man might board nailed with finishing nails to the top pro-

prefer a workbench about 331/2” high. However, tects the bench top and can be changed as often

as needed.

Figure 4: A good basic bench for the beginning gunsmith. As the business expands, and the need for a

larger bench increases, the smaller bench can be used as an auxiliary bench.

170