Page 18 - 11月技术月刊

P. 18

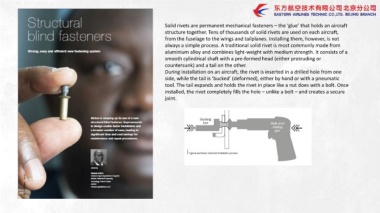

Solid rivets are permanent mechanical fasteners – the ‘glue’ that holds an aircraft

structure together. Tens of thousands of solid rivets are used on each aircraft,

from the fuselage to the wings and tailplanes. Installing them, however, is not

always a simple process. A traditional solid rivet is most commonly made from

aluminium alloy and combines light-weight with medium strength. It consists of a

smooth cylindrical shaft with a pre-formed head (either protruding or

countersunk) and a tail on the other.

During installation on an aircraft, the rivet is inserted in a drilled hole from one

side, while the tail is ‘bucked’ (deformed), either by hand or with a pneumatic

tool. The tail expands and holds the rivet in place like a nut does with a bolt. Once

installed, the rivet completely fills the hole – unlike a bolt – and creates a secure

joint.