Page 140 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 140

Product Design Considerations and General Guidelines

Wall thickness: Thicker the wall, higher is the material cost and cooling time.

Optimum wall thickness for adequate strength and stiffness is desirable. In case of

the double walled parts the walls must not be too close to avoid webbing and voids

formations.

Minimum outside wall separation gap of 5x wall thickness

Minimum inner wall separation gap of 3x wall thickness

Wall thickness is important for corner radii too. Large outside as well as inside radii

are preferable to small radii which allows for more even flow of material. However

due to material flow characteristics outside corners tend to be thicker whereas

projections into the moulding tend to thin out.

Sharp corners: must be avoided as it creates stress point in the product. Provide

minimum radius of 3/16" at corners and generous radii to joining walls (45° and

above).

Wall Thickness tolerance: it is common to specify a minimum wall thickness rather

than a nominal wall thickness. For general purpose parts as tanks and outdoor toys,

the typical wall thickness variation is ±20% whereas ±10% is considered as precise

tolerance.

Draft Angles: These are required to remove the piece from the mould. On the

outside walls, a draft angle of 1° may work (assuming no rough surface or holes). On

inside walls, such as the inside of a boat hull, a draft angle of 5° may be required. This

is due to shrinkage and possible part warping.

Moulds Pieces: The Mould must have least possible number of pieces, ideally a two

piece mould which is easy, convenient to open-close having least maintenance

saving and flat parting line

Parting lines: The less the parting lines on product better it is. For this the number of

mould pieces be minimum which in turn decreases irregularity of parting lines. Also

parting line location is important, to ensure that it does not leave a visible mark on the

moulded part.

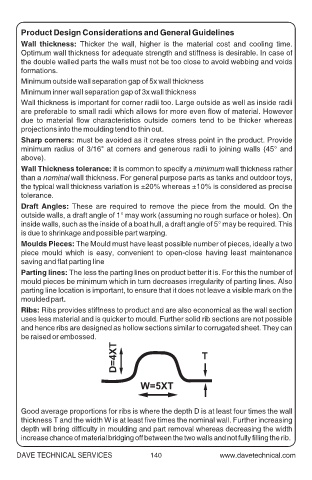

Ribs: Ribs provides stiffness to product and are also economical as the wall section

uses less material and is quicker to mould. Further solid rib sections are not possible

and hence ribs are designed as hollow sections similar to corrugated sheet. They can

be raised or embossed.

D=4XT T

W=5XT

Good average proportions for ribs is where the depth D is at least four times the wall

thickness T and the width W is at least five times the nominal wall. Further increasing

depth will bring difficulty in moulding and part removal whereas decreasing the width

increase chance of material bridging off between the two walls and not fully filling the rib.

DAVE TECHNICAL SERVICES 140