Page 138 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 138

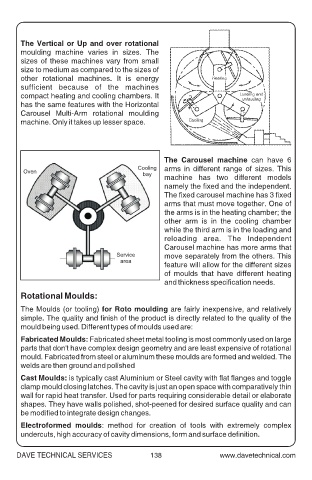

The Vertical or Up and over rotational

moulding machine varies in sizes. The

sizes of these machines vary from small

size to medium as compared to the sizes of

other rotational machines. It is energy

sufficient because of the machines

compact heating and cooling chambers. It

has the same features with the Horizontal

Carousel Multi-Arm rotational moulding

machine. Only it takes up lesser space.

The Carousel machine can have 6

Cooling arms in different range of sizes. This

Oven

bay

machine has two different models

namely the fixed and the independent.

The fixed carousel machine has 3 fixed

arms that must move together. One of

the arms is in the heating chamber; the

other arm is in the cooling chamber

while the third arm is in the loading and

reloading area. The Independent

Carousel machine has more arms that

Service move separately from the others. This

area

feature will allow for the different sizes

of moulds that have different heating

and thickness specification needs.

Rotational Moulds:

The Moulds (or tooling) for Roto moulding are fairly inexpensive, and relatively

simple. The quality and finish of the product is directly related to the quality of the

mould being used. Different types of moulds used are:

Fabricated Moulds: Fabricated sheet metal tooling is most commonly used on large

parts that don't have complex design geometry and are least expensive of rotational

mould. Fabricated from steel or aluminum these moulds are formed and welded. The

welds are then ground and polished

Cast Moulds: is typically cast Aluminium or Steel cavity with flat flanges and toggle

clamp mould closing latches. The cavity is just an open space with comparatively thin

wall for rapid heat transfer. Used for parts requiring considerable detail or elaborate

shapes. They have walls polished, shot-peened for desired surface quality and can

be modified to integrate design changes.

Electroformed moulds: method for creation of tools with extremely complex

undercuts, high accuracy of cavity dimensions, form and surface definition.

DAVE TECHNICAL SERVICES 138