Page 224 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 224

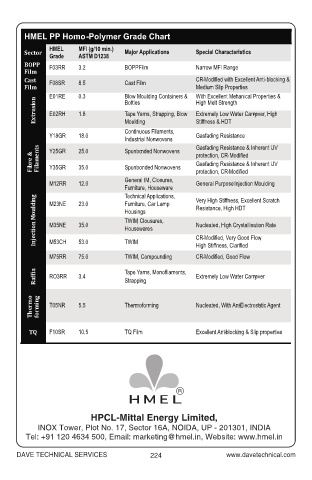

HMEL PP Homo-Polymer Grade Chart

HMEL MFI (g/10 min.)

Sector Major Applications Special Characteristics

Grade ASTM D1238

BOPP F03RR 3.2 BOPPFilm Narrow MFI Range

Film

Cast F08SR 8.5 Cast Film CR-Modified with Excellent Anti-blocking &

Film Medium Slip Properties

E01RE 0.3 Blow Moulding Containers & With Excellent Mechanical Properties &

Extrusion E02RH 1.8 Tape Yarns, Strapping, Blow Extremely Low Water Carry-over, High

High Melt Strength

Bottles

Moulding Stiffness & HDT

Continuous Filaments,

Y18GR 18.0 Gasfading Resistance

Industrial Nonwovens

& Filaments Y25GR 25.0 Spunbonded Nonwovens Gasfading Resistance & Inherent UV

protection, CR-Modified

Fibre Y35GR 35.0 Spunbonded Nonwovens Gasfading Resistance & Inherent UV

protection, CR-Modified

General IM, Closures,

M12RR 12.0 Furniture, Houseware General PurposeInjection Moulding

Technical Applications,

Injection Moulding M23NE 23.0 Furniture, Car Lamp Nucleated, High Crystallisation Rate

Very High Stiffness, Excellent Scratch

Resistance, High HDT

Housings

TWIM, Clousures,

M35NE

35.0

Housewares

CR-Modified , Very Good Flow,

M53CH

53.0 TWIM High Stiffness, Clarified

M75RR 75.0 TWIM, Compounding CR-Modified, Good Flow

Raffia RO3RR 3.4 Tape Yarns, Monofilaments, Extremely Low Water Carry-over

Strapping

Thermo forming T05NR 5.5 Thermoforming Nucleated, With Anti-Electrostatic Agent

TQ F10SR 10.5 TQ Film Excellent Anti-blocking & Slip properties

R

HPCL-Mittal Energy Limited,

INOX Tower, Plot No. 17, Sector 16A, NOIDA, UP - 201301, INDIA

Tel: +91 120 4634 500, Email: marketing@hmel.in, Website: www.hmel.in

DAVE TECHNICAL SERVICES 224 www.davetechnical.com