Page 34 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 34

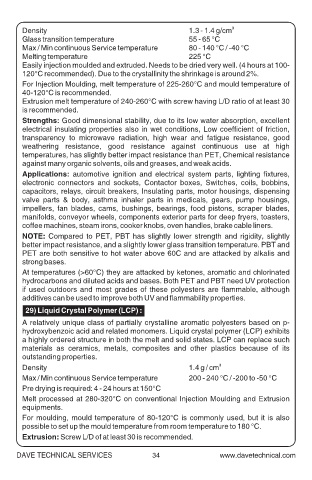

Density 1.3 - 1.4 g/cm 3

Glass transition temperature 55 - 65 °C

Max / Min continuous Service temperature 80 - 140 °C / -40 °C

Melting temperature 225 °C

Easily injection moulded and extruded. Needs to be dried very well. (4 hours at 100-

120°C recommended). Due to the crystallinity the shrinkage is around 2%.

For Injection Moulding, melt temperature of 225-260°C and mould temperature of

40-120°C is recommended.

Extrusion melt temperature of 240-260°C with screw having L/D ratio of at least 30

is recommended.

Strengths: Good dimensional stability, due to its low water absorption, excellent

electrical insulating properties also in wet conditions, Low coefficient of friction,

transparency to microwave radiation, high wear and fatigue resistance, good

weathering resistance, good resistance against continuous use at high

temperatures, has slightly better impact resistance than PET, Chemical resistance

against many organic solvents, oils and greases, and weak acids.

Applications: automotive ignition and electrical system parts, lighting fixtures,

electronic connectors and sockets, Contactor boxes, Switches, coils, bobbins,

capacitors, relays, circuit breakers, Insulating parts, motor housings, dispensing

valve parts & body, asthma inhaler parts in medicals, gears, pump housings,

impellers, fan blades, cams, bushings, bearings, food pistons, scraper blades,

manifolds, conveyor wheels, components exterior parts for deep fryers, toasters,

coffee machines, steam irons, cooker knobs, oven handles, brake cable liners.

NOTE: Compared to PET, PBT has slightly lower strength and rigidity, slightly

better impact resistance, and a slightly lower glass transition temperature. PBT and

PET are both sensitive to hot water above 60C and are attacked by alkalis and

strong bases.

At temperatures (>60°C) they are attacked by ketones, aromatic and chlorinated

hydrocarbons and diluted acids and bases. Both PET and PBT need UV protection

if used outdoors and most grades of these polyesters are flammable, although

additives can be used to improve both UV and flammability properties.

29) Liquid Crystal Polymer (LCP) :

A relatively unique class of partially crystalline aromatic polyesters based on p-

hydroxybenzoic acid and related monomers. Liquid crystal polymer (LCP) exhibits

a highly ordered structure in both the melt and solid states. LCP can replace such

materials as ceramics, metals, composites and other plastics because of its

outstanding properties.

Density 1.4 g / cm 3

Max / Min continuous Service temperature 200 - 240 °C / -200 to -50 °C

Pre drying is required: 4 - 24 hours at 150°C

Melt processed at 280-320°C on conventional Injection Moulding and Extrusion

equipments.

For moulding, mould temperature of 80-120°C is commonly used, but it is also

possible to set up the mould temperature from room temperature to 180 °C.

Extrusion: Screw L/D of at least 30 is recommended.

DAVE TECHNICAL SERVICES 34