Page 29 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 29

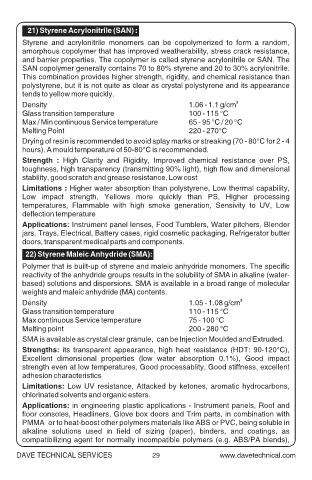

21) Styrene Acrylonitrile (SAN) :

Styrene and acrylonitrile monomers can be copolymerized to form a random,

amorphous copolymer that has improved weatherability, stress crack resistance,

and barrier properties. The copolymer is called styrene acrylonitrile or SAN. The

SAN copolymer generally contains 70 to 80% styrene and 20 to 30% acrylonitrile.

This combination provides higher strength, rigidity, and chemical resistance than

polystyrene, but it is not quite as clear as crystal polystyrene and its appearance

tends to yellow more quickly.

Density 1.06 - 1.1 g/cm 3

Glass transition temperature 100 - 115 °C

Max / Min continuous Service temperature 65 - 95 °C / 20 °C

Melting Point 220 - 270°C

Drying of resin is recommended to avoid splay marks or streaking (70 - 80°C for 2 - 4

hours). A mould temperature of 50-80°C is recommended.

Strength : High Clarity and Rigidity, Improved chemical resistance over PS,

toughness, high transparency (transmitting 90% light), high flow and dimensional

stability, good scratch and grease resistance, Low cost

Limitations : Higher water absorption than polystyrene, Low thermal capability,

Low impact strength, Yellows more quickly than PS, Higher processing

temperatures, Flammable with high smoke generation, Sensivity to UV, Low

deflection temperature

Applications: Instrument panel lenses, Food Tumblers, Water pitchers, Blender

jars, Trays, Electrical, Battery cases, rigid cosmetic packaging, Refrigerator butter

doors, transparent medical parts and components.

22) Styrene Maleic Anhydride (SMA):

Polymer that is built-up of styrene and maleic anhydride monomers. The specific

reactivity of the anhydride groups results in the solubility of SMA in alkaline (water-

based) solutions and dispersions. SMA is available in a broad range of molecular

weights and maleic anhydride (MA) contents.

Density 1.05 - 1.08 g/cm 3

Glass transition temperature 110 - 115 °C

Max continuous Service temperature 75 - 100 °C

Melting point 200 - 280 °C

SMA is available as crystal clear granule, can be Injection Moulded and Extruded.

Strengths: its transparent appearance, high heat resistance (HDT: 90-120°C),

Excellent dimensional properties (low water absorption 0.1%), Good impact

strength even at low temperatures, Good processablity, Good stiffness, excellent

adhesion characteristics

Limitations: Low UV resistance, Attacked by ketones, aromatic hydrocarbons,

chlorinated solvents and organic esters.

Applications: in engineering plastic applications - Instrument panels, Roof and

floor consoles, Headliners, Glove box doors and Trim parts, in combination with

PMMA or to heat-boost other polymers materials like ABS or PVC, being soluble in

alkaline solutions used in field of sizing (paper), binders, and coatings, as

compatibilizing agent for normally incompatible polymers (e.g. ABS/PA blends),

DAVE TECHNICAL SERVICES 29