Page 27 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 27

pentane and isopentane which expand the material to form a cellular structures,

commonly known as Thermocole. It is widely used in many everyday applications

where its light weight (~98% air), strength, durability, thermal insulation and shock

absorption characteristics provide economic, high performance products. It is

normally supplied in sheet form however can also be moulded into shapes or in

large blocks.

Applications: building insulation materials, structural insulated panel building

systems, Packaging of food, meat, fish, fresh fruit, bakery products, eggs,

cushioning fragile items inside boxes, disposable trays, plates, bowls and cups & for

carry-out food packaging (hinged lid containers popularly known as “clam shells”)

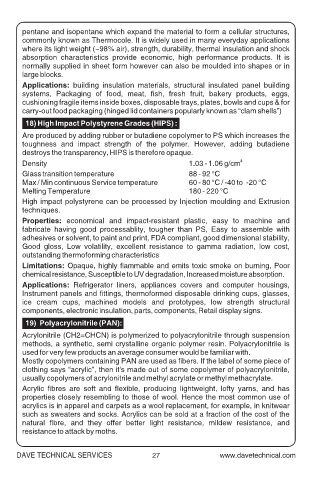

18) High Impact Polystyrene Grades (HIPS) :

Are produced by adding rubber or butadiene copolymer to PS which increases the

toughness and impact strength of the polymer. However, adding butadiene

destroys the transparency, HIPS is therefore opaque.

Density 1.03 - 1.06 g/cm 3

Glass transition temperature 88 - 92 °C

Max / Min continuous Service temperature 60 - 80 °C / -40 to -20 °C

Melting Temperature 180 - 220 °C

High impact polystyrene can be processed by Injection moulding and Extrusion

techniques.

Properties: economical and impact-resistant plastic, easy to machine and

fabricate having good processablity, tougher than PS, Easy to assemble with

adhesives or solvent, to paint and print, FDA compliant, good dimensional stability,

Good gloss, Low volatility, excellent resistance to gamma radiation, low cost,

outstanding thermoforming characteristics

Limitations: Opaque, highly flammable and emits toxic smoke on burning, Poor

chemical resistance, Susceptible to UV degradation, Increased moisture absorption.

Applications: Refrigerator liners, appliances covers and computer housings,

Instrument panels and fittings, thermoformed disposable drinking cups, glasses,

ice cream cups, machined models and prototypes, low strength structural

components, electronic insulation, parts, components, Retail display signs.

19) Polyacrylonitrile (PAN):

Acrylonitrile (CH2=CHCN) is polymerized to polyacrylonitrile through suspension

methods, a synthetic, semi crystalline organic polymer resin. Polyacrylonitrile is

used for very few products an average consumer would be familiar with.

Mostly copolymers containing PAN are used as fibers. If the label of some piece of

clothing says “acrylic”, then it's made out of some copolymer of polyacrylonitrile,

usually copolymers of acrylonitrile and methyl acrylate or methyl methacrylate.

Acrylic fibres are soft and flexible, producing lightweight, lofty yarns, and has

properties closely resembling to those of wool. Hence the most common use of

acrylics is in apparel and carpets as a wool replacement, for example, in knitwear

such as sweaters and socks. Acrylics can be sold at a fraction of the cost of the

natural fibre, and they offer better light resistance, mildew resistance, and

resistance to attack by moths.

DAVE TECHNICAL SERVICES 27