Page 23 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 23

Limitations: Poor heat resistance, reduced barrier properties and creep compared

to LDPE, Attacked by polar solvents, hydrocarbons, oxidants and strong acids

Applications: EVAs are leading polymers for hot-melt manufacturing fulfilling

various requirements in packaging, bookbinding or label sticking. Widely used for

handle grips, flexible tubing, shock absorber in sports shoes for shoe soles, flexible

packaging, shrink wrap, auto bumper pads, flexible toys, ice cube trays, bicycle

saddles, barrel bungs, railway sleeper pads, baby bottle teats, teethers, refrigerator

door gaskets, sealant layer in multilayer films others. The foam is also commonly

used as padding in equipment for various sports such as ski boots, hockey &

boxing. EVA is used in biomedical engineering applications such as drug delivery

device used within the body. While the EVA is not biodegradable within the body, it

is quite inert and causes little or no reaction following implantation.

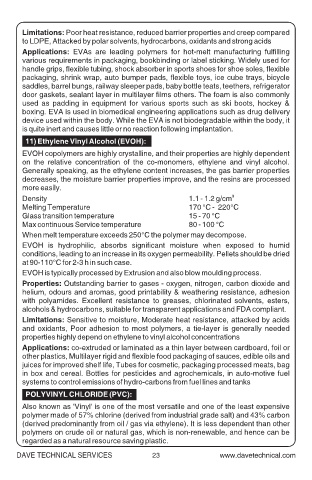

11) Ethylene Vinyl Alcohol (EVOH):

EVOH copolymers are highly crystalline, and their properties are highly dependent

on the relative concentration of the co-monomers, ethylene and vinyl alcohol.

Generally speaking, as the ethylene content increases, the gas barrier properties

decreases, the moisture barrier properties improve, and the resins are processed

more easily.

Density 1.1 - 1.2 g/cm 3

Melting Temperature 170 °C - 220°C

Glass transition temperature 15 - 70 °C

Max continuous Service temperature 80 - 100 °C

When melt temperature exceeds 250°C the polymer may decompose.

EVOH is hydrophilic, absorbs significant moisture when exposed to humid

conditions, leading to an increase in its oxygen permeability. Pellets should be dried

at 90-110°C for 2-3 h in such case.

EVOH is typically processed by Extrusion and also blow moulding process.

Properties: Outstanding barrier to gases - oxygen, nitrogen, carbon dioxide and

helium, odours and aromas, good printability & weathering resistance, adhesion

with polyamides. Excellent resistance to greases, chlorinated solvents, esters,

alcohols & hydrocarbons, suitable for transparent applications and FDA compliant.

Limitations: Sensitive to moisture, Moderate heat resistance, attacked by acids

and oxidants, Poor adhesion to most polymers, a tie-layer is generally needed

properties highly depend on ethylene to vinyl alcohol concentrations

Applications: co-extruded or laminated as a thin layer between cardboard, foil or

other plastics, Multilayer rigid and flexible food packaging of sauces, edible oils and

juices for improved shelf life, Tubes for cosmetic, packaging processed meats, bag

in box and cereal. Bottles for pesticides and agrochemicals, in auto-motive fuel

systems to control emissions of hydro-carbons from fuel lines and tanks

POLYVINYL CHLORIDE (PVC):

Also known as 'Vinyl' is one of the most versatile and one of the least expensive

polymer made of 57% chlorine (derived from industrial grade salt) and 43% carbon

(derived predominantly from oil / gas via ethylene). It is less dependent than other

polymers on crude oil or natural gas, which is non-renewable, and hence can be

regarded as a natural resource saving plastic.

DAVE TECHNICAL SERVICES 23