Page 20 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 20

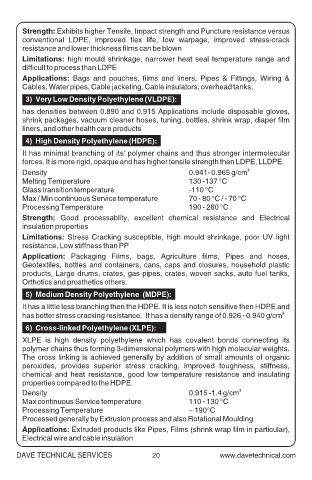

Strength: Exhibits higher Tensile, Impact strength and Puncture resistance versus

conventional LDPE, improved flex life, low warpage, improved stress-crack

resistance and lower thickness films can be blown

Limitations: high mould shrinkage, narrower heat seal temperature range and

difficult to process than LDPE

Applications: Bags and pouches, films and liners, Pipes & Fittings, Wiring &

Cables, Water pipes, Cable jacketing, Cable insulators, overhead tanks,

3) Very Low Density Polyethylene (VLDPE):

has densities between 0.890 and 0.915 Applications include disposable gloves,

shrink packages, vacuum cleaner hoses, tuning, bottles, shrink wrap, diaper film

liners, and other health care products

4) High Density Polyethylene (HDPE):

It has minimal branching of its' polymer chains and thus stronger intermolecular

forces. It is more rigid, opaque and has higher tensile strength then LDPE, LLDPE.

Density 0.941- 0.965 g/cm 3

Melting Temperature 130 -137 °C

Glass transition temperature -110 °C

Max / Min continuous Service temperature 70 - 80 °C / - 70 °C

Processing Temperature 190 - 280 °C

Strength: Good processablity, excellent chemical resistance and Electrical

insulation properties

Limitations: Stress Cracking susceptible, high mould shrinkage, poor UV light

resistance, Low stiffness than PP

Application: Packaging Films, bags, Agriculture films, Pipes and hoses,

Geotextiles, bottles and containers, cans, caps and closures, household plastic

products, Large drums, crates, gas pipes, crates, woven sacks, auto fuel tanks,

Orthotics and prosthetics others.

5) Medium Density Polyethylene (MDPE):

It has a little less branching then the HDPE. It is less notch sensitive then HDPE and

has better stress cracking resistance. It has a density range of 0.926 - 0.940 g/cm 3

6) Cross-linked Polyethylene (XLPE):

XLPE is high density polyethylene which has covalent bonds connecting its

polymer chains thus forming 3-dimensional polymers with high molecular weights.

The cross linking is achieved generally by addition of small amounts of organic

peroxides, provides superior stress cracking, improved toughness, stiffness,

chemical and heat resistance, good low temperature resistance and insulating

properties compared to the HDPE.

Density 0.915 -1.4 g/cm 3

Max continuous Service temperature 110 - 130 °C

Processing Temperature ~ 190°C

Processed generally by Extrusion process and also Rotational Moulding

Applications: Extruded products like Pipes, Films (shrink wrap film in particular),

Electrical wire and cable insulation

DAVE TECHNICAL SERVICES 20