Page 22 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 22

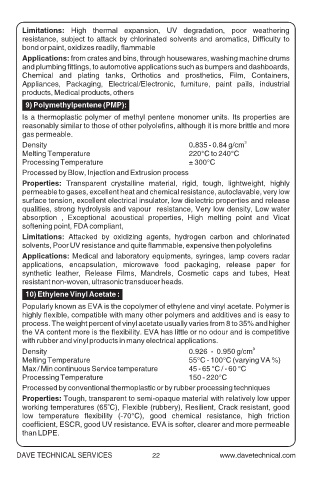

Limitations: High thermal expansion, UV degradation, poor weathering

resistance, subject to attack by chlorinated solvents and aromatics, Difficulty to

bond or paint, oxidizes readily, flammable

Applications: from crates and bins, through housewares, washing machine drums

and plumbing fittings, to automotive applications such as bumpers and dashboards,

Chemical and plating tanks, Orthotics and prosthetics, Film, Containers,

Appliances, Packaging, Electrical/Electronic, furniture, paint pails, industrial

products, Medical products, others

9) Polymethylpentene (PMP):

Is a thermoplastic polymer of methyl pentene monomer units. Its properties are

reasonably similar to those of other polyolefins, although it is more brittle and more

gas permeable.

Density 0.835 - 0.84 g/cm 3

Melting Temperature 220°C to 240°C

Processing Temperature ± 300°C

Processed by Blow, Injection and Extrusion process

Properties: Transparent crystalline material, rigid, tough, lightweight, highly

permeable to gases, excellent heat and chemical resistance, autoclavable, very low

surface tension, excellent electrical insulator, low dielectric properties and release

qualities, strong hydrolysis and vapour resistance, Very low density, Low water

absorption , Exceptional acoustical properties, High melting point and Vicat

softening point, FDA compliant,

Limitations: Attacked by oxidizing agents, hydrogen carbon and chlorinated

solvents, Poor UV resistance and quite flammable, expensive then polyolefins

Applications: Medical and laboratory equipments, syringes, lamp covers radar

applications, encapsulation, microwave food packaging, release paper for

synthetic leather, Release Films, Mandrels, Cosmetic caps and tubes, Heat

resistant non-woven, ultrasonic transducer heads.

10) Ethylene Vinyl Acetate :

Popularly known as EVA is the copolymer of ethylene and vinyl acetate. Polymer is

highly flexible, compatible with many other polymers and additives and is easy to

process. The weight percent of vinyl acetate usually varies from 8 to 35% and higher

the VA content more is the flexibility. EVA has little or no odour and is competitive

with rubber and vinyl products in many electrical applications.

Density 0.926 - 0.950 g/cm 3

Melting Temperature 55°C - 100°C (varying VA %)

Max / Min continuous Service temperature 45 - 65 °C / - 60 °C

Processing Temperature 150 - 220°C

Processed by conventional thermoplastic or by rubber processing techniques

Properties: Tough, transparent to semi-opaque material with relatively low upper

o

working temperatures (65 C), Flexible (rubbery), Resilient, Crack resistant, good

low temperature flexibility (-70°C), good chemical resistance, high friction

coefficient, ESCR, good UV resistance. EVA is softer, clearer and more permeable

than LDPE.

DAVE TECHNICAL SERVICES 22