Page 19 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 19

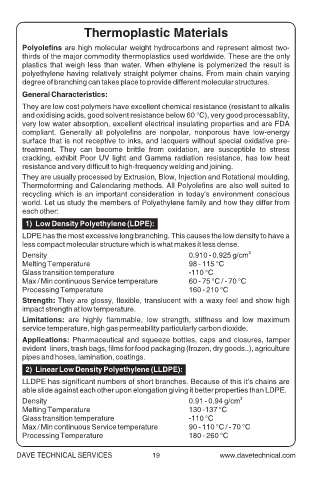

Thermoplastic Materials

Polyolefins are high molecular weight hydrocarbons and represent almost two-

thirds of the major commodity thermoplastics used worldwide. These are the only

plastics that weigh less than water. When ethylene is polymerized the result is

polyethylene having relatively straight polymer chains. From main chain varying

degree of branching can takes place to provide different molecular structures.

General Characteristics:

They are low cost polymers have excellent chemical resistance (resistant to alkalis

and oxidising acids, good solvent resistance below 60 °C), very good processablity,

very low water absorption, excellent electrical insulating properties and are FDA

compliant. Generally all polyolefins are nonpolar, nonporous have low-energy

surface that is not receptive to inks, and lacquers without special oxidative pre-

treatment. They can become brittle from oxidation, are susceptible to stress

cracking, exhibit Poor UV light and Gamma radiation resistance, has low heat

resistance and very difficult to high-frequency welding and joining.

They are usually processed by Extrusion, Blow, Injection and Rotational moulding,

Thermoforming and Calendaring methods. All Polyolefins are also well suited to

recycling which is an important consideration in today's environment conscious

world. Let us study the members of Polyethylene family and how they differ from

each other:

1) Low Density Polyethylene (LDPE):

LDPE has the most excessive long branching. This causes the low density to have a

less compact molecular structure which is what makes it less dense.

Density 0.910 - 0.925 g/cm 3

Melting Temperature 98 - 115 °C

Glass transition temperature -110 °C

Max / Min continuous Service temperature 60 - 75 °C / - 70 °C

Processing Temperature 160 - 210 °C

Strength: They are glossy, flexible, translucent with a waxy feel and show high

impact strength at low temperature.

Limitations: are highly flammable, low strength, stiffness and low maximum

service temperature, high gas permeability particularly carbon dioxide.

Applications: Pharmaceutical and squeeze bottles, caps and closures, tamper

evident liners, trash bags, films for food packaging (frozen, dry goods..), agriculture

pipes and hoses, lamination, coatings.

2) Linear Low Density Polyethylene (LLDPE):

LLDPE has significant numbers of short branches. Because of this it’s chains are

able slide against each other upon elongation giving it better properties than LDPE.

Density 0.91 - 0.94 g/cm 3

Melting Temperature 130 -137 °C

Glass transition temperature -110 °C

Max / Min continuous Service temperature 90 - 110 °C / - 70 °C

Processing Temperature 180 - 260 °C

DAVE TECHNICAL SERVICES 19