Page 67 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 67

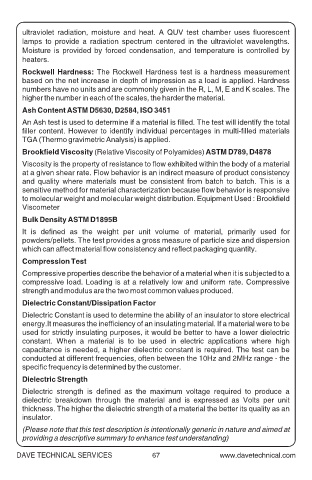

ultraviolet radiation, moisture and heat. A QUV test chamber uses fluorescent

lamps to provide a radiation spectrum centered in the ultraviolet wavelengths.

Moisture is provided by forced condensation, and temperature is controlled by

heaters.

Rockwell Hardness: The Rockwell Hardness test is a hardness measurement

based on the net increase in depth of impression as a load is applied. Hardness

numbers have no units and are commonly given in the R, L, M, E and K scales. The

higher the number in each of the scales, the harder the material.

Ash Content ASTM D5630, D2584, ISO 3451

An Ash test is used to determine if a material is filled. The test will identify the total

filler content. However to identify individual percentages in multi-filled materials

TGA (Thermo gravimetric Analysis) is applied.

Brookfield Viscosity (Relative Viscosity of Polyamides) ASTM D789, D4878

Viscosity is the property of resistance to flow exhibited within the body of a material

at a given shear rate. Flow behavior is an indirect measure of product consistency

and quality where materials must be consistent from batch to batch. This is a

sensitive method for material characterization because flow behavior is responsive

to molecular weight and molecular weight distribution. Equipment Used : Brookfield

Viscometer

Bulk Density ASTM D1895B

It is defined as the weight per unit volume of material, primarily used for

powders/pellets. The test provides a gross measure of particle size and dispersion

which can affect material flow consistency and reflect packaging quantity.

Compression Test

Compressive properties describe the behavior of a material when it is subjected to a

compressive load. Loading is at a relatively low and uniform rate. Compressive

strength and modulus are the two most common values produced.

Dielectric Constant/Dissipation Factor

Dielectric Constant is used to determine the ability of an insulator to store electrical

energy.It measures the inefficiency of an insulating material. If a material were to be

used for strictly insulating purposes, it would be better to have a lower dielectric

constant. When a material is to be used in electric applications where high

capacitance is needed, a higher dielectric constant is required. The test can be

conducted at different frequencies, often between the 10Hz and 2MHz range - the

specific frequency is determined by the customer.

Dielectric Strength

Dielectric strength is defined as the maximum voltage required to produce a

dielectric breakdown through the material and is expressed as Volts per unit

thickness. The higher the dielectric strength of a material the better its quality as an

insulator.

(Please note that this test description is intentionally generic in nature and aimed at

providing a descriptive summary to enhance test understanding)

DAVE TECHNICAL SERVICES 67