Page 63 - C:\Users\Adik\Documents\Flip PDF Professional\Marketer PPT LR\

P. 63

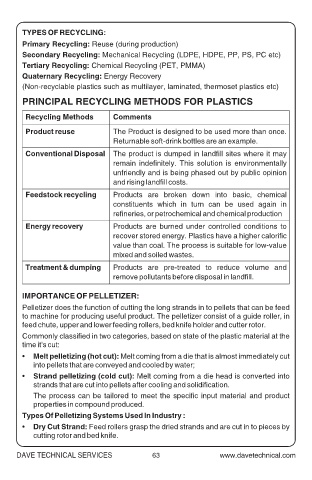

TYPES OF RECYCLING:

Primary Recycling: Reuse (during production)

Secondary Recycling: Mechanical Recycling (LDPE, HDPE, PP, PS, PC etc)

Tertiary Recycling: Chemical Recycling (PET, PMMA)

Quaternary Recycling: Energy Recovery

(Non-recyclable plastics such as multilayer, laminated, thermoset plastics etc)

PRINCIPAL RECYCLING METHODS FOR PLASTICS

Recycling Methods Comments

Product reuse The Product is designed to be used more than once.

Returnable soft-drink bottles are an example.

Conventional Disposal The product is dumped in landfill sites where it may

remain indefinitely. This solution is environmentally

unfriendly and is being phased out by public opinion

and rising landfill costs.

Feedstock recycling Products are broken down into basic, chemical

constituents which in turn can be used again in

refineries, or petrochemical and chemical production

Energy recovery Products are burned under controlled conditions to

recover stored energy. Plastics have a higher calorific

value than coal. The process is suitable for low-value

mixed and soiled wastes.

Treatment & dumping Products are pre-treated to reduce volume and

remove pollutants before disposal in landfill.

IMPORTANCE OF PELLETIZER:

Pelletizer does the function of cutting the long strands in to pellets that can be feed

to machine for producing useful product. The pelletizer consist of a guide roller, in

feed chute, upper and lower feeding rollers, bed knife holder and cutter rotor.

Commonly classified in two categories, based on state of the plastic material at the

time it's cut:

• Melt pelletizing (hot cut): Melt coming from a die that is almost immediately cut

into pellets that are conveyed and cooled by water;

• Strand pelletizing (cold cut): Melt coming from a die head is converted into

strands that are cut into pellets after cooling and solidification.

The process can be tailored to meet the specific input material and product

properties in compound produced.

Types Of Pelletizing Systems Used In Industry :

• Dry Cut Strand: Feed rollers grasp the dried strands and are cut in to pieces by

cutting rotor and bed knife.

DAVE TECHNICAL SERVICES 63