Page 259 - Parker - Hydraulic and Lube Filtration Products

P. 259

Static Control Filter Elements

Together we can… Studies have suggested Micro-glass to less effi cient

that varnish is formed due Cellulose fi lter media and

P reserve the environment. to the thermal and oxidative also to decrease fl ow density

Minimize waste and promote degradation of oil. It also by operating duplexing fi lter

energy effi ciency. has been suggested that the changeover valves in the center

localized heat generated from position. Parker Static Control

A chieve worldwide a static charge discharge can fi lter elements eliminate these

fi ltration solutions. reach several thousand degrees. compromises and ensure proper

Build global confi dence. Hot enough to cause localized system fi ltration performance.

thermal degradation of the oil.

R edefi ne new limits. The static discharge can also

Forge ahead with advanced cause pitting of metallic surfaces

technology.

in a system.

K eep contamination under Manufacturers of combustion

control.

Reduce maintenance costs. turbines have recognized the

relationship of static discharge

E nhance total system reliability. causing thermal degradation

Focus on customer and subsequent varnish

satisfaction. formation to the extent that they

have suggested turbine users

R each optimum potential. to choose coarser fi ltration,

Drill to greater depths. including switching from

…engineer your success.

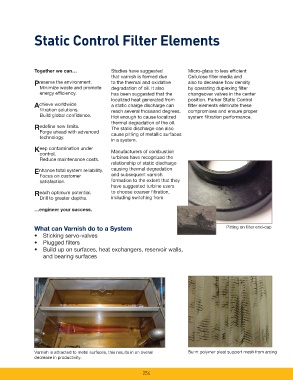

What can Varnish do to a System Pitting on fi lter end-cap

• Sticking servo-valves

• Plugged fi lters

• Build up on surfaces, heat exchangers, reservoir walls,

and bearing surfaces

Varnish is attracted to metal surfaces, this results in an overall Burnt polymer pleat support mesh from arcing

decrease in productivity.

254