Page 13 - Parker - Bottled water filtration

P. 13

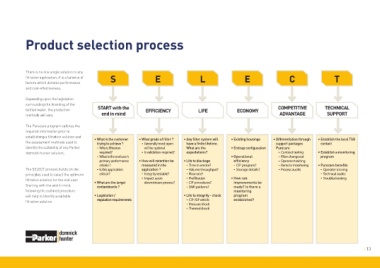

Product selection process

There is no one single solution to any

filtration application, it is a balance of S E L E C T

factors which dictates performance

and cost-effectiveness.

Depending upon the legislation

surrounding the branding of the

bottled water, the production START with the EFFICIENCY LIFE ECONOMY COMPETITIVE TECHNICAL

methods will vary. end in mind ADVANTAGE SUPPORT

The Purecare program outlines the

required information prior to

establishing a filtration solution and • What is the customer • What grade of filter ? • Any filter system will • Existing housings • Differentiation through • Establish the local TSG

the assessment methods used to trying to achieve ? - Generally most open have a finite lifetime. support packages contact

identify the suitability of any Parker - Why is filtration will be optimal What are the • Endcap configuration Purecare

domnick hunter solution. required? - Is validation required? expectations? - Contract testing • Establish a monitoring

- What is the end user’s • Operational - Filter changeout program

primary performance • How will retention be • Life to blockage efficiency - Operator training

criteria ? measured in the - Time in service? - CIP program? - Remote monitoring • Purecare benefits

The SELECT process builds on the - Is this application application ? - Volume throughput? - Storage details? - Process audits - Operator training

principles used to select the optimum critical ? - Integrity testable? - Flow rate? - Technical audits

- Impact upon - Prefiltration • How can - Troubleshooting

filtration solution for the end user. • What are the target downstream process? - CIP procedures? improvements be

Starting with the end in mind, contaminants ? - Shift patterns? made? Is there a

following the outlined procedure monitoring

will help to identify a suitable • Legislation / • Life to integrity - check program

filtration solution. regulation requirements - CIP /SIP details established?

- Pressure shock

- Thermal shock

| 13