Page 11 - Parker - Bottled water filtration

P. 11

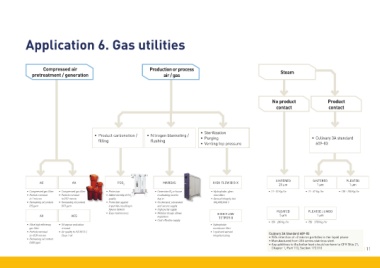

Application 6. Gas utilities

Compressed air Production or process

pretreatment / generation air / gas Steam

No product Product

contact contact

• Sterilization

• Product carbonation / • Nitrogen blanketing / • Purging • Culinary 3A standard

filling flushing

• Venting top pressure 609-03

SINTERED SINTERED PLEATED

AO AA PCO MAXIGAS HIGH FLOW BIO-X

2 25 µm 1 µm 1 µm

• Compressed gas filter • Compressed gas filter • Protection • Generates N 2 in-house • Hydrophobic glass • 21 - 82 Kg / hr • 21 - 82 Kg / hr • 150 - 280 Kg / hr

• Particle removal • Particle removal • Added sterility of CO 2 irradicating need to microfibre

to 1 micron to 0.01 micron quality buy in • Aerosol integrity test

• Remaining oil content • Remaining oil content • Protection against • On demand, convenient VALAIRDATA 3

0.5 ppm 0.01 ppm impurities resulting in and secure supply

flavour defects • High purity supply

• Easy maintenance • Modular design allows HIGH FLOW PLEATED PLEATED JUMBO

AX ACS expansion TETPOR II 5 µm 1 µm

• Cost-effective supply • 150 - 280 Kg / hr • 750 - 3750 Kg / hr

• Ultra high efficiency • Oil vapour and odour • Hydrophobic

gas filter removal membrane filter

• Particle removal • Air quality to ISO 8573.1; • Liquid and aerosol Culinary 3A Standard 609-03

to <0.01 micron Class 1 oil integrity testing

• Remaining oil content • 95% retention of >2 micron particles in the liquid phase

• Manufactured from 316 series stainless steel

0.001 ppm

• Any additives to the boiler feed should conform to CFR Title 21,

Chapter 1, Part 173, Section 173.310 | 11