Page 7 - Parker - Bottled water filtration

P. 7

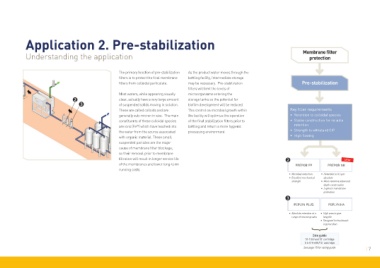

Application 2. Pre-stabilization

Understanding the application Membrane filter

protection

The primary function of pre-stabilization As the product water moves through the

filters is to protect the final membrane bottling facility, intermediate storage

filters from colloidal particulate. may be necessary. Pre-stabilization Pre-stabilization

filters will limit the levels of

Most waters, while appearing visually microorganisms entering the

➋ clear, actually have a very large amount storage tanks so the potential for

➌ of suspended solids moving in solution. biofilm development will be reduced.

These are called colloids and are This control on microbial growth within Key filter requirements

generally sub-micron in size. The main the facility will optimize the operation • Retention to colloidal species

constituents of these colloidal species of the final stabilization filters prior to • Stable construction for reliable

are ions (Fe ) which have leached into bottling and return a more hygienic retention

3+

the water from the source associated processing environment. • Strength to withstand CIP

with organic material. These small, • High flowing

suspended particles are the major

cause of membrane filter blockage,

so their removal prior to membrane

filtration will result in longer service life ➋ NEW

of the membranes and lower long-term PREPOR PP PREPOR NG

running costs.

• Microbial reduction • Retention to 0.5 µm

• Excellent mechanical absolute

strength • More retentive advanced

depth construction

• Superior membrane

protection

➌

PEPLYN PLUS PEPLYN HA

• Absolute retention at a • High area to give

range of micron grades long life

• Designed for backwash

regeneration

}

Size guide

10-15l/min/10¨cartridge

0.6-0.9m 3 /h/10¨cartridge

See page 15 for rating guide | 7