Page 6 - Parker - Bottled water filtration

P. 6

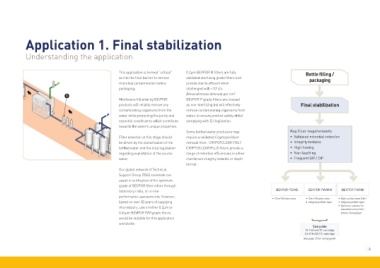

Application 1. Final stabilization

Understanding the application

This application is termed “critical” 0.2µm BEVPOR M filters are fully Bottle filling /

as it is the final barrier to remove validated sterilizing grade filters and packaging

microbial contamination before provide sterile effluent when

packaging. challenged with >10 cfu

7

➊ Brevundimonas diminuta per cm . 2

Membrane filtration by BEVPOR BEVPOR P grade filters are classed

products will reliably remove any as non-sterilizing but will effectively Final stabilization

contaminating organisms from the remove contaminating organisms from

water while protecting the purity and water, to ensure product safety whilst

essential constituents which contribute complying with EU legislation.

towards the water’s unique properties.

Some bottled water producers may Key filter requirements

Filter selection at this stage should require a validated Cryptosporidium • Validated microbial retention

be driven by the classification of the removal filter. CRYPOTCLEAR PES / • Integrity testable

bottled water and the local legislation CRYPTOCLEAR PLUS filters provide a • High flowing

regarding exploitation of the source range of retention efficiencies in either • Non-leaching

water. membrane integrity testable or depth • Frequent SIP / CIP

format.

Our global network of Technical

Support Group (TSG) scientists can

assist in verification of the optimum

grade of BEVPOR filter either through

laboratory trials, or in-line BEVPOR PS/MS BEVPOR PW/MW BEVPOR PH/MH

performance assessments. However, • 0.6m 2 filtration area • 0.6m 2 filtration area • High surface area 0.8m 2

based on over 30 years of supplying • Integral prefilter layer • Integral prefilter layer

this industry, use of either 0.2µm or • Optimum solution for

extended service life /

0.45µm BEVPOR P/M grade filters volume throughput

would be suitable for this application

worldwide. }

Size guide

10-15l/min/10¨cartridge

0.6-0.9m 3 /h/10¨cartridge

See page 15 for rating guide

| 6