Page 101 - Schroeder - Hydraulic And Lube Filtration

P. 101

Base-Ported Pres sure Fil ter KF30

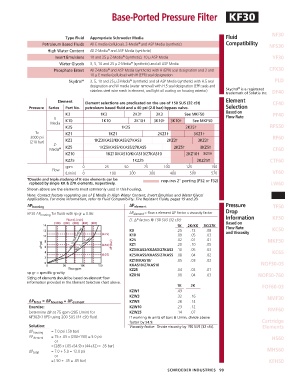

Type Fluid Appropriate Schroeder Media Fluid NF30

®

Petroleum Based Fluids All E media (cellulose), Z-Media and ASP Media (synthetic) Compatibility NFS30

High Water Content All Z-Media and ASP Media (synthetic)

®

®

Invert Emulsions 10 and 25 µ Z-Media (synthetic), 10 µ ASP Media YF30

®

Water Glycols 3, 5, 10 and 25 µ Z-Media (synthetic) and all ASP Media

®

Phosphate Esters All Z-Media and ASP Media (synthetic) with H (EPR) seal designation and 3 and CFX30

10 µ E media (cellulose) with H (EPR) seal designation

Skydrol ® 3, 5, 10 and 25 µ Z-Media (synthetic) and all ASP Media (synthetic) with H.5 seal PLD

®

designation and W media (water removal) with H.5 seal designation (EPR seals and ®

stainless steel wire mesh in element, and light oil coating on housing exterior) Skydrol is a registered DF40

trademark of Solutia Inc.

Element Element selections are predicated on the use of 150 SUS (32 cSt) Element CF40

Pressure Series Part No. petroleum based fluid and a 40 psi (2.8 bar) bypass valve. Selection

Based on

K3 1K3 2K3† 3K3 See MKF50 PF40

E Flow Rate

Media K10 1K10 2K10† 3K10† 3K10† See MKF50

K25 1K25 2K25† RFS50

To KZ1 1KZ1 2KZ1† 3KZ1†

3000 psi RF60

(210 bar) KZ3 1KZ3/KAS3/KKAS3/27KAS3 2KZ3† 3KZ3†

Z-

Media ® KZ5 1KZ5/KAS5/KKAS5/27KAS5 2KZ5† 3KZ5† CF60

KZ10 1KZ10/KAS10/KKAS10/27KAS10 2KZ10† 3KZ10†

KZ25 1KZ25 2KZ25† CTF60

gpm 0 25 50 75 100 125 150

Flow VF60

(L/min) 0 100 200 300 400 500 570

† Double and triple stacking of K-size elements can be requires 2" porting (P32 or F32)

replaced by single KK & 27K elements, respectively. LW60

Shown above are the elements most commonly used in this housing.

Note: Contact factory regarding use of E Media in High Water Content, Invert Emulsion and Water Glycol KF30

Applications. For more information, refer to Fluid Compatibility: Fire Resistant Fluids, pages 19 and 20.

∆P housing ∆P element Pressure TF50

KF30 ∆P housing for fluids with sp gr = 0.86: ∆P element = flow x element ∆P factor x viscosity factor Drop

El. ∆P factors @ 150 SUS (32 cSt): Information KF50

Based on

1K 2K/KK 3K/27K Flow Rate

K3 .25 .12 .08 and Viscosity KC50

K10 .09 .05 .03

K25 .02 .01 .01 MKF50

KZ1 .20 .10 .05

KZ3/KAS3/KKAS3/27KAS3 .10 .05 .03 KC65

KZ5/KAS5/KKAS5/27KAS5 .08 .04 .02

KZ10/KAS10/ .05 .03 .02

KKAS10/27KAS10 NOF30-05

KZ25 .04 .02 .01

sp gr = specific gravity KZX10 .08 .04 .03 NOF50-760

Sizing of elements should be based on element flow

information provided in the Element Selection chart above.

1K 2K FOF60-03

KZW1 .43

KZW3 .32 .16 NMF30

∆P filter = ∆P housing + ∆P element KZW5 .28 .14

Exercise: KZW10 .23 .12 RMF60

Determine ∆P at 75 gpm (285 L/min) for KZW25 .14 .07

KF302K10PD using 200 SUS (44 cSt) fluid. If working in units of bars & L/min, divide above

factor by 54.9. Cartridge

Solution: Viscosity factor: Divide viscosity by 150 SUS (32 cSt). Elements

∆P housing = 7.0 psi [.50 bar]

∆P element = 75 x .05 x (200÷150) = 5.0 psi HS60

or

= [285 x (.05÷54.9) x (44÷32) = .35 bar]

∆P total = 7.0 + 5.0 = 12.0 psi MHS60

or

= [.50 + .35 = .85 bar] KFH50

SCHROEDER INDUSTRIES 99