Page 253 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 253

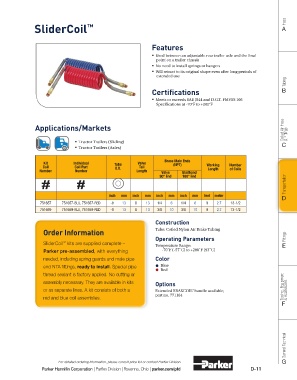

SliderCoil ™ A Hose

Features

Used between an adjustable rear trailer axle and the final

point on a trailer chassis

No need to install springs or hangers

Will retract to its original shape even after long periods of

extended use

Tubing

Certifications B

Meets or exceeds SAE J844 and D.O.T. FMVSS 106

Specifications at -70°F to +200°F

Coiled Air Hose & Fittings

Applications/Markets

Tractor Trailers (Sliding) C

Tractor Trailers (Axles)

Brass Male Ends

Kit Individual Tube Valve (NPT)

Coil Coil Part O.D. Tail Working Number

Number Number Length Valve Gladhand Length of Coils

90° End 180° End

Transportation

inch mm inch mm inch mm inch mm feet meter

D

751657 751657-BLU, 751657-RED -8 13 8 13 1/4 6 1/4 6 9 2.7 13-1/2

751659 751659-BLU, 751659-RED -8 13 8 13 3/8 10 3/8 10 9 2.7 13-1/2

Construction

Order Information Tube: Coiled Nylon Air Brake Tubing

Operating Parameters Fittings

SliderCoil kits are supplied complete – Temperature Range: E

™

Parker pre-assembled, with everything -70˚F (-57˚C) to +200˚F (93˚C)

needed, including spring guards and male pipe Color

end NTA fittings, ready to install. Special pipe Blue

Red

thread sealant is factory applied. No cutting or

assembly necessary. They are available in kits Options

or as separate lines. A kit consists of both a Extended BRAKCOIL® handle available, Tooling, Equipment & Accessories

part no. 771164

red and blue coil assemblies.

F

General Technical

For detailed ordering information, please consult price list or contact Parflex Division. G

Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd D-11