Page 394 - Parker Parflex Thermoplastic & Fluoropolymer Products Hose, Tubing, & Fittings 2017 - Cat 4460

P. 394

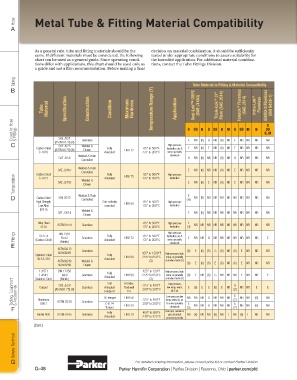

Hose Metal Tube & Fitting Material Compatibility

A

As a general rule, tube and fitting materials should be the decision on material combination, it should be sufficiently

same. If different materials must be considered, the following tested under appropriate conditions to assure suitability for

chart can be used as a general guide. Since operating condi- the intended application. For additional material combina-

tions differ with applications, this chart should be used only as tions, contact the Tube Fittings Division.

a guide and not a firm recommendation. Before making a final

Tubing Tube Material to Fitting & Material Compatibility

B

Tube Material Specification Construction Condition Maximum Hardness Temperature Range (7) Application Seal-Lok™ ORFS (SAE J1453) Triple-Lok ® 37° Flare (SAE J514) Ferulok ® Flareless (SAE J514) Intru-Lok ® Flareless EO/EO-2 Flareless (ISO 8434-1)

Coiled Air Hose & Fittings S SS B S SS B M S SS M B B, M

S

SS

SAE J524

Seamless

C (ASTM A179) (8) Welded & High pressure E NR (6) G NR (6) NR E NR NR NR NR

SAE J525

Carbon Steel (ASTM A178) (8) Drawn Fully HRB 72 -65° to 500°F hydraulics, air, & E NR (6) E NR (6) NR E NR NR NR NR

C-1010 Annealed -55° to 260°C some specialty

Welded & Flash chemicals

SAE J356 G NR (6) NR NR (6) NR G NR NR NR NR

Controlled

Welded & Flash

SAE J2467 E NR (6) NR NR (6) NR E NR NR NR NR

-65° to 500°F

Fully

Carbon Steel Controlled Annealed HRB 75 -55° to 260°C High pressure

Transportation SAE J2435 Welded & E NR (6) E NR (6) NR E NR NR NR NR

hydraulics

C-1021

Drawn

E

D Carbon Steel SAE 2613 Welded & Flash (10) NR (6) NR NR NR NR NR NR NR NR NR

Controlled

High Strength Sub-critically HRB 90 -65° to 500°F High pressure

Low Alloy annealed -55° to 260°C hydraulics

(HSLA) Welded &

SAE J2614 E NR (6) NR NR NR NR NR NR NR NR NR

Drawn

Alloy Steel ASTM A519 Seamless -65° to 500°F High pressure E NR NR NR NR NR NR NR NR NR NR NR

4130 -55° to 260°C hydraulics (4)

High pressure

Fittings (Carbon Steel) DIN 2391 Seamless Annealed HRB 72 -55° to 260°C hydraulics, air, & E NR NR G NR NR NR NR NR NR NR E

Fully

-65° to 500°F

St 37.4

Part 2

some specialty

E (Metric) chemicals

ASTM A213 Seamless (6) E (6) (6) G (6) NR (6) E NR NR NR

ASTM A269 -425° to 1200°F High pressure, high

Stainless Steel Fully HRB 90 -255° to 650°C temp, or generally

304 & 316 Annealed

ASTM A249 Welded & (3) corrosive media (1) (6) E (6) (6) E (6) NR (6) E NR NR NR

ASTM A269 Drawn

1.4571 DIN 17458 Fully -425° to 120°F High pressure, high

Tab 8

1.4541 (Metric) Seamless Annealed HRB 90 -255° to 650°C corrosive media (1) (6) E NR (6) G NR NR NR E NR NR E

temp, or generally

(3)

Stainless Steel

Tooling, Equipment & Accessories Aluminum (ASTM B-75) (8) Seamless T6 Temper 60 Max. -325° to 400°F temp, water, oil, air NR (6) E G G NR NR NR (2) NR NR (6) NR

Soft

Low pressure,

G

SAE J528

low temp, water,

NR

E

Copper

(6)

E

E

E

Rockwell

Annealed

-200° to 205°C

oil & air

Temper 0

15T

E

Low pressure,low

HRB 56

NR NR

NR NR

-325° to 400°F

(2)

0 & T4

E

& some specialty

E

chemicals

F 6061 ASTM-B210 Seamless Temper HRB 30 -200° to 205°C Sour gas, marine & (5) NR NR G NR NR NR (2) NR NR (6) NR

Monel 400 ASTM-B165 Seamless Fully HRB 70 -400° to 800°F gen chemical NR (6) NR NR (6) NR E NR (6) E NR NR

Annealed -240° to 425°C processing media

(Cont.)

General Technical

G For detailed ordering information, please consult price list or contact Parflex Division.

G-48 Parker Hannifin Corporation | Parflex Division | Ravenna, Ohio | parker.com/pfd