Page 4 - Parker - Oil and gas downstream applications filtration products for hyrdotreating

P. 4

de

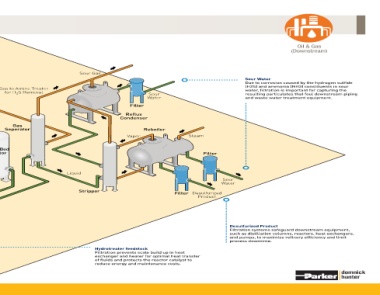

Oil & Gas (Downstream) Due to corrosion caused by the hydrogen sulfi (H2S) and ammonia (NH3) constituents in sour water , filtration is important for capturing the resulting particulates that foul downstream piping and waste water treatment equipment. Filtration systems safeguard downstream equipment, such as distillation columns, reactors, heat exchangers, nery efficiency and limit

Sour Water Desulfurized Product and pumps, to maximize refi process downtime.

Sour Water

Filter Desulfurized Product

Steam

Filter

Sour Water Reboiler exchanger and heater for optimal heat transfer

Filter Reflux Condenser Vapor Hydrotreater feedstock Filtration prevents scale build up in heat of fluids and protects the reactor catalyst to reduce energy and maintenance costs.

Sour Gas Stripper

Liquid

Gas to Amine Treater for H 2 S Removal Gas Seperator

Gas Fixed-Bed Reactor

Fired Heater Feed

Purge Gas Lean Amine Rich Amine Heat Exchanger Filter

Pump

Contactor Make-up Hydrogen

Sulfer-free Gas Filter Hydrogen Rich Recycle Gas Make-up hydrogen Filtration protects system performance by removing particulate from the hydrogen stream prior to entering the petrochemical feed stock.

Hydrotreating Recycle Gas Compressor

life and ensures that the equipment maintains

Filtration of lube oil extends compressor

functionality by avoiding damage caused

Hydrotreating

Process Overview

Filter

Lube Oil

Lube Oil by particulate.