Page 23 - Parker - General Technical

P. 23

4300 Catalog General Technical

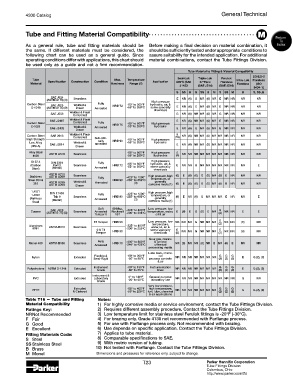

Tube and Fitting Material Compatibility M

Return

To

As a general rule, tube and fitting materials should be Before making a final decision on material combination, it Index

the same. If different materials must be considered, the should be sufficiently tested under appropriate conditions to

following chart can be used as a general guide. Since assure suitability for the intended application. For additional

operating conditions differ with applications, this chart should material combinations, contact the Tube Fittings Division.

be used only as a guide and not a firm recommendation.

Tube Material to Fitting & Material Compatibility

EO/EO-2

Tube Max. Temperature Seal-Lok Triple-Lok Ferulok Intru-Lok Flareless

Material Specification Construction Condition Hardness Range (7) Application ORFS (SAE 37°Flare Flareless Flareless (ISO

J1453 (SAE J514) (SAE J514)

8434-1)

S SS B S SS B M S SS M B S, SS ,B

SAE J524

(ASTM A179) (8) Seamless High pressure E NR (6) G NR (6) NR E NR NR NR NR

Carbon Steel SAE J525 Welded & Fully -65° to 500°F hydraulic, air, &

C-1010 (ASTM A178) (8) Drawn Annealed HRB 72 -55° to 260°C some specialty E NR (6) E NR (6) NR E NR NR NR NR

chemicals

SAE J356 Welded & Flash G NR (6) NR NR (6) NR G NR NR NR NR

Controlled

SAE J2467 Welded & Flash E NR (6) NR NR (6) NR E NR NR NR NR

Carbon Steel Controlled Fully HRB 75 -65° to 500°F High pressure

C-1021 Welded & Annealed -55° to 260°C hydraulic

SAE J2435 Drawn E NR (6) E NR (6) NR E NR NR NR NR

E

Carbon Steel SAE 2613 Welded & Flash (10) NR (6) NR NR (6) NR NR NR NR NR NR

Controlled

High Strength Sub-criti- -65° to 500°F High pressure

cally

Low Alloy SAE J2614 Welded & annealed HRB 90 -55° to 260°C hydraulic E NR (6) NR NR (6) NR NR NR NR NR NR

(HSLA) Drawn

Alloy Steel ASTM A519 Seamless -65° to 500°F High pressure E NR NR NR NR NR NR NR NR NR NR NR

4130 -55° to 260°C hydraulics (4)

St 37.4 DIN 2391 Fully High pressure

(Carbon Part 2 Seamless HRB 72 -65° to 500°F hydraulic, air, & E NR NR G NR NR NR NR NR NR NR E

some specialty

-55° to 260°C

Steel) (Metric) Annealed chemicals

ASTM A213

Stainless ASTM A269 Seamless Fully -425° to 1200° High pressure, high (6) E (6) (6) G (6) NR (6) E NR NR NR

Steel 304 & Welded & HRB 90 -255° to 650°C temperature, or

generally

316 ASTM A249 Drawn Annealed (3) corrosive media (1) (6) E (6) (6) E (6) NR (6) E NR NR NR

ASTM A269

1.4571 High pressure, high

1.4541 DIN 17458 Fully -425° to 1200° temperature, or

Tab 8

Stainless (Metric) Seamless Annealed HRB 90 -255° to 650°C generally (6) E NR (6) G NR NR NR E NR NR E

(3)

Steel corrosive media (1)

Soft 60 Max. Low pressure, low

G

SAE J528

Copper (ASTM B-75) (8) Seamless Annealed Rockwell -325° to 400°F temperature, water, E (6) E G (6) E NR (2) NR NR E E

-200° to 205°C

Temper 0 15T oil & air

E

T6 Temper HRB 56 Low pressure, low NR NR NR G NR NR NR (2) NR NR (6) NR

temperature,

Aluminum ASTM-B210 Seamless -325° to 400°F water,oil, air &

6061 0 & T4 -200° to 205°C some specialty E E

Temper HRB 30 chemicals (5) NR NR G NR NR NR (2) NR NR (6) NR

Sour gas, marine

Fully -400° to 800°F & general

Monel 400 ASTM-B165 Seamless HRB 70 NR (6) NR NR (6) NR E NR (6) E NR NR

Annealed -240° to 425°C chemical

processing media

Lube lines, chemi-

G

G

cal

G

Flexible &

Nylon Extruded Semi-Rigid -60° to 200°F process controls NR NR NR NR NR NR NR (2) (2) (2) E G (2), (9)

-50° to 95°C

& air

G

G

G

Polyethylene ASTM D-1248 Extruded Instrument -80° to 150°F Instrumentation NR NR NR NR NR NR NR (2) (2) (2) E G (2), (9)

lines

-60° to 65°C

Grade

Instrument &

0° to 140°F

PVC Extruded Laboratory -20° to 60°C General purpose NR NR NR NR NR NR NR NR NR NR G NR

laboratory use

Grade

Very low pressure,

G

G

Extruded

high temperature,

G

PFTE & Cintered -65° to 400°F fuel, lube, chemical NR NR NR NR NR NR NR (2) (2) (2) G G (2), (9)

-55° to 205°C

& air applications

Table T16 — Tube and Fitting Notes:

Material Compatibility 1) For highly corrosive media or service environment, contact the Tube Fittings Division.

Ratings Key: 2) Requires different assembly procedure. Contact the Tube Fittings Division.

NR Not Recommended 3) Low temperature limit for stainless steel Ferulok fittings is -20°F (-30°C).

F Fair 4) For brazing only. Grade 4130 not recommended with Parflange process.

G Good 5) For use with Parflange process only. Not recommended with brazing.

E Excellent 6) Use depends on specific application. Contact the Tube Fittings Division.

Fitting Materials Code: 7) Applies to tube material.

S Steel 8) Comparable specifications to SAE.

SS Stainless Steel 9) With metric version of tubing.

B Brass 10) Not tested with Parflange. Contact the Tube Fittings Division.

M Monel Dimensions and pressures for reference only, subject to change.

T23 Parker Hannifin Corporation

Tube Fittings Division

Columbus, Ohio

http://www.parker.com/tfd