Page 379 - Schmalz - Vacuum Components

P. 379

5_Kap_Greifsysteme_2016_EN_Vakuum-Greifsysteme_2016 25.02.16 17:48 Seite 379

PA01019111_inh_EN.pdf

Vacuum Area Gripping Systems FXP / FMP

Product Specifications

PA01019111_inh_EN.pdf Note on Configuration PA01019111_inh_EN.pdf

Tests with the original workpieces are necessary to ensure that the area gripping system functions properly. We will gladly

conduct these for you in our test center in order to find the best solution for your application. Schmalz - The Company

Vacuum Knowledge

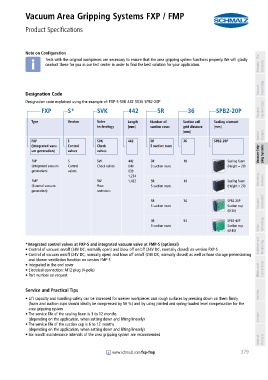

Designation Code

Designation code explained using the example of: FXP-S-SVK 442 5R36 SPB2-20P

Vacuum

FXP S* SVK 442 5R 36 SPB2-20P Suction Cups

Type Version Valve Length Number of Suction cell Sealing element

technology [mm] suction rows grid distance [mm]

[mm]

Special Grippers

FXP S SVK 442 5R 36 SPB2-20P

Vacuum Grip- ping Systems

(Integrated vacu- Control Check 5 suction rows

um generation) valves valves

FXP S SVK 442 3R 18 Sealing foam

(Integrated vacuum Control Check valves 640 3 suction rows (Height = 20)

generation) valves 838

1,234

FMP SW 1,432 5R 18 Sealing foam Mounting Elements

(External vacuum Flow 5 suction rows (Height = 20)

generation) restrictors

5R 36 SPB2-20P Generators

5 suction rows Suction cup Vacuum

(Ø 20)

3R 54 SPB2-40P

3 suction rows Suction cup Valve Technology

(Ø 40)

*Integrated control valves at FXP-S and integrated vacuum valve at FMP-S (optional) Switches and

• Control of vacuum on/off (24V DC, normally open) and blow off on/off (24V DC, normally closed) on version FXP-S Monitoring

• Control of vacuum on/off (24V DC, normally open) and blow off on/off (24V DC, normally closed) as well as hose storage pretensioning

and blower ventilation function on version FMP-S

• Integrated in the end cover

• Electrical connection: M12 plug (4-pole) Filters and Connections

• Part number on request

Service and Practical Tips

• Lift capacity and handling safety can be increased for uneven workpieces and rough surfaces by pressing down on them firmly Services

(foam and suction cups should ideally be compressed by 50 %) and by using jointed and spring-loaded level compensation for the

area gripping system

• The service life of the sealing foam is 3 to 12 months

(depending on the application, when setting down and lifting linearly) Contact

• The service life of the suction cup is 6 to 12 months

(depending on the application, when setting down and lifting linearly)

• Six-month maintenance intervals of the area gripping system are recommended

Index of Products

www.schmalz.com/fxp-fmp 379

PA01019111_inh_EN.pdf