Page 27 - Parker - The Handbook of Hydraulic Filtration

P. 27

Filter Housing Selection

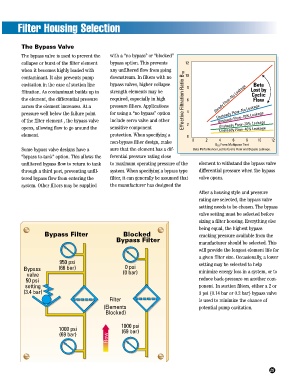

The Bypass Valve

The bypass valve is used to prevent the with a “no bypass” or “blocked”

collapse or burst of the filter element bypass option. This prevents 12

when it becomes highly loaded with any unfiltered flow from going

contaminant. It also prevents pump downstream. In filters with no 10

cavitation in the case of suction line bypass valves, higher collapse 8 Beta

filtration. As contaminant builds up in strength elements may be Lost by

Cyclic

the element, the differential pressure required, especially in high Effective Filtration Ratio B 10 6 Steady Flow–No Leakage Flow

across the element increases. At a pressure filters. Applications

pressure well below the failure point for using a “no bypass” option 4 Unsteady Flow–No Leakage

of the filter element , the bypass valve include servo valve and other Unsteady Flow–10% Leakage

opens, allowing flow to go around the sensitive component 2 Unsteady Flow–20% Leakage

Unsteady Flow–40% Leakage

element. protection. When specifying a 0

non-bypass filter design, make 0 2 4 6 8 10 12

B 10 From Multipass Test

Some bypass valve designs have a sure that the element has a dif- Beta Performance Lost by Cyclic Flow and Bypass Leakage.

“bypass to-tank” option. This allows the ferential pressure rating close

unfiltered bypass flow to return to tank to maximum operating pressure of the element to withstand the bypass valve

through a third port, preventing unfil- system. When specifying a bypass type differential pressure when the bypass

tered bypass flow from entering the filter, it can generally be assumed that valve opens.

system. Other filters may be supplied the manufacturer has designed the

After a housing style and pressure

rating are selected, the bypass valve

setting needs to be chosen. The bypass

valve setting must be selected before

sizing a filter housing. Everything else

being equal, the highest bypass

Bypass Filter Blocked cracking pressure available from the

Bypass Filter

manufacturer should be selected. This

will provide the longest element life for

a given filter size. Occasionally, a lower

950 psi setting may be selected to help

Bypass (66 bar) 0 psi minimize energy loss in a system, or to

valve (0 bar)

50 psi reduce back-pressure on another com-

setting ponent. In suction filters, either a 2 or

(3.4 bar) 3 psi (0.14 bar or 0.2 bar) bypass valve

Filter is used to minimize the chance of

(Elements potential pump cavitation.

Blocked)

1000 psi

1000 psi (69 bar)

(69 bar)

Flow

25