Page 10 - Linde - Model code edition X-02 series product

P. 10

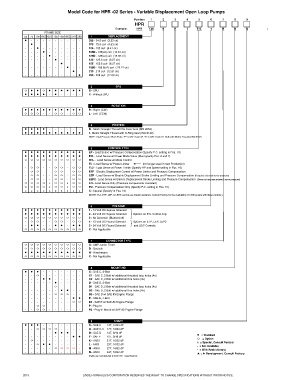

Model Code for HPR -02 Series - Variable Displacement Open Loop Pumps

Position 1 2 3 4 5 6 7 8 9

HPR

Example: HPR 135 S R I E1L 1 H D D M250

FRAME SIZE

55 75 105 105D125D 135 165 165D 210 280 1 DISPLACEMENT

l - - - - - - - - - 055 - 54.8 cc/r (3.35 cir)

- l - - - - - - - - 075 - 75.9 cc/r (4.63 cir)

- - l - - - - - - - 105 - 105 cc/r (6.41 cir)

- - - l - - - - - - 105D - 105(x2) cc/r (12.81 cir)

- - - - l - - - - - 125D - 126(x2) cc/r (15.38 cir)

- - - - - l - - - - 135 - 135.6 cc/r (8.27 cir)

- - - - - - l - - - 165 - 165.6 cc/r (8.27 cir)

- - - - - - - l - - 165D - 165.6(x2) cc/r ( 20.21 cir)

- - - - - - - - l - 210 - 210 cc/r (12.81 cir)

- - - - - - - - - l 280 - 280 cc/r (17.08 cir)

2 SPU

m l l m l l l l l l S - SPU

l l l l - l - - - - X - Without SPU

3 ROTATION

l l l l l l l l l l R - Right (CW)

m m m - - m m - m m L - Left (CCW)

4 PORTING

l l l l - - - - - - D - Metric Straight Thread Flat Face Seal (DIN 3852)

l l l l l l l l l l I - Metric Straight Thread with O-Ring Seal (ISO 6149)

NOTE: High Pressure Work Ports: "P" is SAE Code 62. "S" is SAE Code 61. Both with Metric Threads (ISO 6162)

5 CONTROL TYPE

l l l l l l l l l l LP - Load Sense w/ Pressure Compensation (Specify P.C. setting in Pos. 10)

l l l l l l l l l l E1L - Load Sense w/ Power Mode Valve (Must specify Pos. 6 and 7)

m m m m m m m m m m H1L - Load Sense w/ Mode Control

- - - - - - - - - - TL - Load Sense w/ Power Limiter (no longer used in new Production)

- m m - - m m - m m TL2 - Load Sense w/ Power Limiter (Specify HP and Speed setting in Pos. 16)

- m m - - m m - m m ETP - Electric Displcement Control w/ Power Limiter and Pressure Compensation

- m m - - m m - m m LEP - Load Sense w/ Electric Displacement Stroke Limiting and Pressure Compensation (Requires external servo pressure)

- m m - - m m - m m LEP2 - Load Sense w/ Electric Displacement Stroke Limiting and Pressure Compensation (Does not requires external servo pressure)

m m m m c m m c m m LO - Load Sense Only (Pressure compensator canceled)

m m m m c m m c m m PO - Pressure Compensation Only (Specify P.C. setting in Pos. 10)

c c c c c c c c c c X - Special (Specify in Pos. 16)

(NOTE: TL2, ETP, LEP, & LEP2 controls are rotation sensitive. Consult Factory for the availability of CCW pumps with these controls.).

6 VOLTAGE

l l l l l l l l l l 1 - 12 Volt DC Square Solenoid

l l l l l l l l l l 2 - 24 Volt DC Square Solenoid Options on E1L Control only

m m m m m m m m m m 3 - No Solenoid (Blanked off)

- m m - - m m - m m 4 - 12 Volt DC Round Solenoid Options on ETP, LEP, LEP2

- l l - - l l - l l 5 - 24 Volt DC Round Solenoid and LEiP Controls.

m m m m m m m m m m X - Not Applicable

7 CONNECTOR TYPE

m m m m m m m m m m A - AMP Junior-Timer

m m m m m m m m m m D - Deutsch

l l l l l l l l l l H - Hirschmann

m m m m m m m m m m X - Not Applicable

8 MOUNTING

l l l - - - - - - - C - SAE C, 2-Bolt

- - m - - - - - - - C1 - SAE C, 2 Bolt w/ additional threaded face holes (4x)

- - - l l - - - - - C2 - SAE C, 2 Bolt w/ additional thru holes (4x)

- - - - - l - - - - D - SAE D, 2-Bolt

- - - - - m - - - - D1 - SAE D, 2 Bolt w/ additional threaded face holes (4x)

- - - - - - l l - - D2 - SAE D, 2 Bolt w/ additional thru holes (4x)

- - - - - m m m - - D3 - SAE D w/ SAE #3 Engine Flange

- - - - - - - - l l E - SAE E, 4-Bolt

- - - - - - - - m m E3 - SAE E w/ SAE #3 Engine Flange

- - m m - - - - - - P - Plug-In

- - m m - - - - - - P3 - Plug-In Mount w/ SAE #3 Engine Flange

9 SHAFT

l l l - - - - - - - C - SAE C 14T, 12/24 dP

- - m m m m - - - - G - SAE C-C 17T, 12/24 dP

- - - - - l l l - - D - SAE D 13T, 8/16 dP l = Standard

- - - - - - - - l l F - SAE F 15T, 8/16 dP

m = Option

- m - - - - - - - - K - ANSI 21T, 16/32 dP c = Special, Consult Factory

- - m l l - - - - - L - ANSI 23T, 16/32 dP

- = Not Available

- - - - - m m m m - M - ANSI 27T, 16/32 dP

* = With Restriction(s)

- - - - - - - - - m N - ANSI 33T, 16/32 dP

p = In Development. Consult Factory.

Shafts are manufactured to ANSI B92.1 specifications

2015 LINDE HYDRAULICS CORPORATION RESERVES THE RIGHT TO CHANGE SPECIFICATIONS WITHOUT PRIOR NOTICE.