Page 114 - Brass, Composite and Thermoplastic Fittings and Valves

P. 114

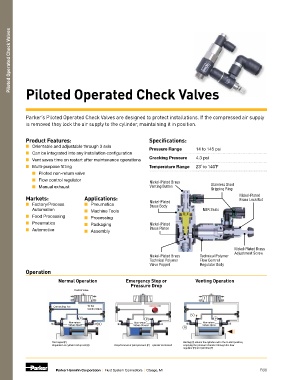

Piloted Operated Check Valves

Piloted Operated Check Valves

Parker’s Piloted Operated Check Valves are designed to protect installations. If the compressed air supply

is removed they lock the air supply to the cylinder, maintaining it in position.

Product Features: Specifications:

■ Orientable and adjustable through 3 axis

Pressure Range 14 to 145 psi

■ Can be integrated into any installation configuration

Cracking Pressure 4.3 psi

■ Vent saves time on restart after maintenance operations

■ Multi-purpose fitting Temperature Range 23˚ to 140˚F

■ Piloted non-return valve

■ Flow control regulator Nickel-Plated Brass

■ Manual exhaust Venting Button Stainless Steel

Gripping Ring

Markets: Applications: Nickel-Plated

Brass Lock Nut

■ Factory/Process ■ Pneumatics Nickel-Plated

Brass Body

Automation ■ Machine Tools NBR Seals

■ Food Processing ■ Processing

■ Pneumatics ■ Packaging Nickel-Plated

■ Automotive ■ Assembly Brass Piston

Nickel-Plated Brass

Adjustment Screw

Nickel-Plated Brass Technical Polymer

Technical Polymer Flow Control

Valve Poppet Regulator Body

Operation

Normal Operation Emergency Stop or Venting Operation

Pressure Drop

Control Valve

Connecting Tee To the

Control Valve

V

P P P

Non-return Non-return Non-return

Valves Open R Valves Closed Valves Open

R

Pilot signal (P) Venting (V) returns the cylinder rod to the to start position,

Regulation of cylinder rod speed (R) Drop/removal of pilot pressure (P) = cylinder rod locked emptying the pressure chamber through the ow

regulator (R) and pilot line (P)

Parker Hannifin Corporation | Fluid System Connectors | Otsego, MI B30