Page 28 - Parker - Energy Products Division - Multitube (Instrument and Heat Trace Tubing Products)

P. 28

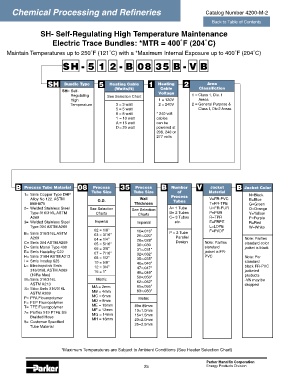

Chemical Processing and Refineries Catalog Number 4200-M-2

Back to Table of Contents

SH- Self-Regulating High Temperature Maintenance

Electric Trace Bundles: *MTR = 400˚F (204˚C)

Maintain Temperatures up to 250˚F (121˚C) with a *Maximum Internal Exposure up to 400˚F (204˚C)

SH - 5 1 2 - B 08 35 B - V B

SH Bundle Type 5 Heating Cable 1 Heating 2 Area

(Watts/ft) Cable Classifiction

SH= Self- Voltage

Regulating See Selection Chart 1 = Class 1, Div. 1

High 1 = 120V Areas

Temperature 3 = 3 watt 2 = 240V 2 = General Purpose &

5 = 5 watt Class I, Div.2 Areas

8 = 8 watt * 240 volt

1 = 10 watt cables

A = 15 watt can be

D = 20 watt powered at

208, 240 or

277 volts

B Process Tube Material 08 Process 35 Process B Number V Jacket B Jacket Color

Tube Size Tube Size of Material

1= Smls Copper Type DHP Process N=Black

Alloy No 122. ASTM O.D. Wall Tubes V=FR-PVC B=Blue

B68-B75 Thickness T=FR-TPE G=Green

2= Welded Stainless Steel See Selection See Selection A= 1 Tube U=FR-PUR O=Orange

Type 316/316L ASTM Charts Charts B= 2 Tubes P=PUR Y=Yellow

A269 C= 3 Tubes R=TPR P=Purple

3= Welded Stainless Steel Imperial Imperial etc. E=FRPE R=Red

Type 304 ASTM A269 L=LDPE W=White

02 = 1/8” 16=.016” F=PVDF

B= Smls 316/316L ASTM 03 = 3/16” 20=.020” P = 2 Tube

A269 04 = 1/4” 28=.028” Parallel Note: Parflex

C= Smls 304 ASTM A269 05 = 5/16” 30=.030 Design Note: Parflex standard color

D= Smls Monel Type 400 06 = 3/8” 31=.031” standard jacket is black

E= Smls Hastelloy C22 07 = 7/16” 32=.032” jacket is FR-

H= Smls 316H ASTM A213 08 = 1/2” 35=.035” PVC Note: For

I = Smls Incoloy 825 10 = 5/8” 40=.040” standard

L= Electropolish Smls 12 = 3/4” 47=.047” black FR-PVC

316/316L ASTM A269 16 = 1” 49=.049” jacketed

(10Ra Max) 50=.050” products

M= Smls 316/316L Metric 62=.062” -VN may be

ASTM A213 dropped

MA = 2mm 65=.065”

S= Silco Smls 316/316L

ASTM A269 MB = 4mm 83=.083”

P= PFA Flouropolymer MC = 6mm Metric

MD = 8mm

F= FEP Fluoropolymer

T= TFE Fluoropolymer ME = 10mm 89=.89mm

MF = 12mm 10=1.0mm

7= Parflex 919 PTFE SS MG = 14mm

Braided Hose 15=1.5mm

MH = 16mm 20=2.0mm

9= Customer Specified

25=2.5mm

Tube Material

*Maximum Temperatures are Subject to Ambient Conditions (See Heater Selection Chart)

Parker Hannifin Corporation

25 Energy Products Division 26