Page 2 - Exlar - TRITEX linear and rotary electric actuation

P. 2

Three need for pneumatic and hydraulic industrial grade enclosure. This

eliminates both the external

cylinders while improving posi-

Technologies– tion performance, reducing cycle servo amplifi er and the expen-

sive and failure prone cables

times and eliminating the main-

One Actuator tenance associated with fl uid associated with a typical servo

system. Servo system com-

power devices.

Exlar’s Tritex™ Series actuators ponent selection, design and

combine three technologies to Ball screw mechanisms, or sepa- installation are completely

deliver for the fi rst time a truly rately mounted gear reducers are eliminated. Trouble shooting

simple and low-cost electric also a thing of the past. Rotary- and debugging of individual

alternative for fl uid power actua- to-linear converters or mechani- components; gear reducers,

tors and costly servo systems. cal reducers necessary to move rotary-to-linear converter mech-

the load are embedded into the anisms and the complex wiring

Tritex actuators represent an Tritex design. layout typical of such a system

all-electric actuator solution are gone. Moreover, the panel

for moving and positioning Less is More space for a separately mounted

mechanical devices in a large The Tritex Series of electric amplifi er and installation of that

variety of commercial, industrial actuators combine a brushless amplifi er are no longer neces-

or military grade applications. motor, servo amplifi er and posi- sary.

Tritex actuators eliminate the tion controller in a single

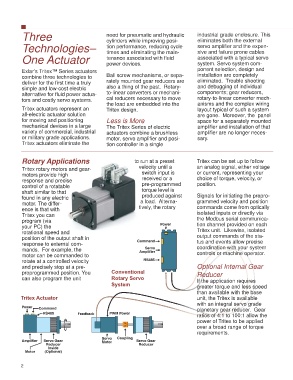

Rotary Applications to run at a preset Tritex can be set up to follow

Tritex rotary motors and gear- velocity until a an analog signal, either voltage

motors provide high switch input is or current, representing your

response and precise received or a choice of torque, velocity, or

control of a rotatable pre-programmed position.

shaft similar to that torque level is

found in any electric produced against Signals for initiating the prepro-

motor. The differ- a load. Alterna- grammed velocity and position

ence is that with tively, the rotary commands come from optically

Tritex you can isolated inputs or directly via

program (via the Modbus serial communica-

your PC) the 0OWER tion channel provided on each

rotational speed and Tritex unit. Likewise, isolated

position of the output shaft in output commands of the sta-

response to external com- #OMMAND tus and events allow precise

mands. For example, the !MPLIFIER coordination with your system

3ERVO

motor can be commanded to controls or machine operator.

rotate at a controlled velocity 23

and precisely stop at a pre- Optional Internal Gear

proprogrammed position. You Conventional Reducer

can also program the unit Rotary Servo If the application requires

System greater torque and less speed

than available with the base

Tritex Actuator unit, the Tritex is available

with an integral servo grade

0OWER

#OMMAND planetary gear reducer. Gear

23 &EEDBACK 07- 0OWER ratios of 4:1 to 100:1 allow the

power of Tritex to be applied

over a broad range of torque

requirements.

3ERVO #OUPLING

!MPLIFIER 3ERVO 'EAR -OTOR 3ERVO 'EAR

2EDUCER 2EDUCER

)NSIDE

-OTOR /PTIONAL

2