Page 1 - Destaco - Clean Room Grippers

P. 1

Clean Room Grippers

Product Overview

DE-STA-CO’s Clean Room Rated Solutions are geared toward laboratory,

semiconductor, medical, and food handling type environments. Many of our

pneumatic products include a scavenge or purge port. These extra ports create

internal vacuum or pressure to control contaminants escaping into the environment

or prevent de-greaser or other chemicals penetrating our product.

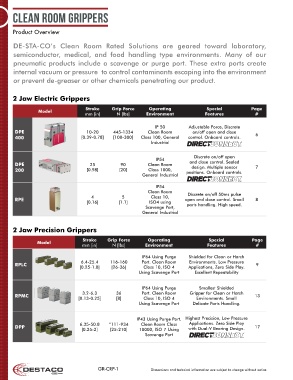

2 Jaw Electric Grippers

Stroke Grip Force Operating Special Page

Model

mm [in] N [lbs] Environment Features #

IP 50 Adjustable Force, Discrete

DPE 10-20 445-1334 Clean Room on/off open and close 6

400 [0.39-0.78] [100-300] Class 100, General control. Onboard controls.

Industrial

TM

Discrete on/off open

IP54

DPE 25 90 Clean Room and close control. Sealed 7

design. Multiple sensor

200 [0.98] [20] Class 1000, positions. Onboard controls.

General Industrial

TM

IP54

Clean Room Discrete on/off 50ms pulse

4 5 Class 10,

RPE open and close control. Small 8

[0.16] [1.1] ISO4 using parts handling. High speed.

Scavenge Port,

General Industrial

2 Jaw Precision Grippers

Stroke Grip Force Operating Special Page

Model

mm [in] N [lbs] Environment Features #

IP64 Using Purge Shielded for Clean or Harsh

6.4-25.4 116-160 Port. Clean Room Environments. Low Pressure

RPLC 9

[0.25-1.0] [26-36] Class 10, ISO 4 Applications, Zero Side Play.

Using Scavenge Port Excellent Repeatability

IP64 Using Purge Smallest Shielded

3.2-6.3 36 Port. Clean Room Gripper for Clean or Harsh

RPMC 13

[0.13-0.25] [8] Class 10, ISO 4 Environments. Small

Using Scavenge Port Delicate Parts Handling.

IP43 Using Purge Port. Highest Precision, Low Pressure

6.35-50.8 “111-934 Clean Room Class Applications. Zero Side Play

DPP 17

[0.25-2] [25-210] 10000, ISO 7 Using with Dual-V Bearing Design.

Scavenge Port

TM

GR-CRP-1 Dimensions and technical information are subject to change without notice