Page 13 - Eaton - Automatic self-cleaning family

P. 13

////////////////////////

TECHNICAL INFORMATION

Model 2596 Automatic Self-Cleaning Strainers

Mechanically Cleaned Filters & Strainer

Revolutionary Arm

5

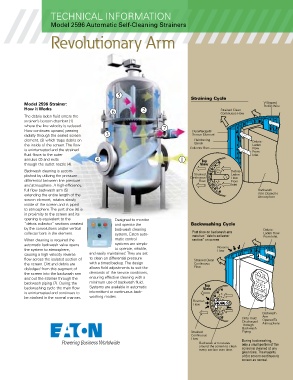

Straining Cycle

Model 2596 strainer: V-Shaped

Profile Wire

How it Works 2 Strained Clean

6 Continuous Flow

The debris-laden fluid enters the

strainer’s bottom chamber (1)

where the line velocity is reduced. 7

Flow continues upward, passing DuraWedge®

radially through the sealed screen 3 Screen Element

element, (2) which traps debris on Reinforcing Debris-

the inside of the screen. The flow Bands Laden

is uninterrupted and the strained Collector Bars Flow

From

fluid flows to the outer Inlet

annulus (3) and exits 4 1 Top

through the outlet nozzle (4). View

Backwash cleaning is accom- Debris-

Strained

plished by utilizing the pressure Continuous Laden

Flow

differential between line pressure Flow From

and atmosphere. A high-efficiency, Inlet

full flow backwash arm (5) Backwash

extending the entire length of the Arm Closed To

Atmosphere

screen element, rotates slowly

inside of the screen and is piped

to atmosphere. The port shoe (6) is

in proximity to the screen and its

opening is equivalent to the Designed to monitor

“debris collector” sections created and operate the Backwashing Cycle

by the convolutions and/or vertical backwash cleaning Debris-

collector bars in the element. system, Eaton auto- Port shoe on backwash arm Laden Flow

matches “debris collector

From Inlet

When cleaning is required the matic control section” on screen

automatic backwash valve opens systems are simple

the system to atmosphere, to operate, reliable, Reverse

Flow

causing a high velocity reverse and easily maintained. They are set

flow across the isolated section of to clean on differential pressure Strained Clean

the screen. Dirt and debris are with a timed backup. The design Continuous

dislodged from this segment of allows field adjustments to suit the Flow

the screen into the backwash arm demands of the service conditions,

and out the strainer through the ensuring effective cleaning with a

backwash piping (7). During the minimum use of backwash fluid. Top

backwashing cycle the main flow Systems are available in automatic View

is uninterrupted and continues to intermittent or continuous back-

be strained in the normal manner. washing modes.

Reverse

Flow

Backwash

Dirty Fluid Arm

Discharged Opened To

Through Atmosphere

Backwash

Strained Piping

Continuous

Flow During backwashing,

Backwash arm rotates only a small portion of the

around the screen to clean

every section over time. screen is cleaned at any

given time. The majority

of the screen continues to

screen as normal.