Page 189 - Mechatronics with Experiments

P. 189

MECHANISMS FOR MOTION TRANSMISSION 175

Gear shift

lever

R to synchronizers S1, S2, S3

G4

G3

G2 G1

Gear

1 Gear Gear

Clutch 2 3 Gear Gear Output

4 reverse shaft to

N eng S1 differential

w out

w in

From

engine S2 N 62 S3

N 12 N 22

Idles to

reverse

direction

N 61

N 11

N 21

N 0 Counter shaft

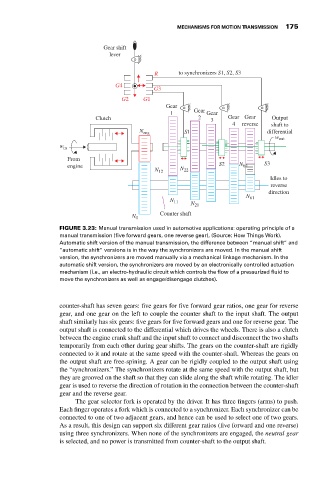

FIGURE 3.23: Manual transmission used in automotive applications: operating principle of a

manual transmission (five forward gears, one reverse gear), (Source: How Things Work).

Automatic shift version of the manual transmission, the difference between “manual shift” and

“automatic shift” versions is in the way the synchronizers are moved. In the manual shift

version, the synchronizers are moved manually via a mechanical linkage mechanism. In the

automatic shift version, the synchronizers are moved by an electronically controlled actuation

mechanism (i.e., an electro-hydraulic circuit which controls the flow of a pressurized fluid to

move the synchronizers as well as engage/disengage clutches).

counter-shaft has seven gears: five gears for five forward gear ratios, one gear for reverse

gear, and one gear on the left to couple the counter shaft to the input shaft. The output

shaft similarly has six gears: five gears for five forward gears and one for reverse gear. The

output shaft is connected to the differential which drives the wheels. There is also a clutch

between the engine crank shaft and the input shaft to connect and disconnect the two shafts

temporarily from each other during gear shifts. The gears on the counter-shaft are rigidly

connected to it and rotate at the same speed with the counter-shaft. Whereas the gears on

the output shaft are free-spining. A gear can be rigidly coupled to the output shaft using

the “synchronizers.” The synchronizers rotate at the same speed with the output shaft, but

they are grooved on the shaft so that they can slide along the shaft while rotating. The idler

gear is used to reverse the direction of rotation in the connection between the counter-shaft

gear and the reverse gear.

The gear selector fork is operated by the driver. It has three fingers (arms) to push.

Each finger operates a fork which is connected to a synchronizer. Each synchronizer can be

connected to one of two adjacent gears, and hence can be used to select one of two gears.

As a result, this design can support six different gear ratios (five forward and one reverse)

using three synchronizers. When none of the synchronizers are engaged, the neutral gear

is selected, and no power is transmitted from counter-shaft to the output shaft.