Page 744 - Mechatronics with Experiments

P. 744

730 MECHATRONICS

.

1 θ S1 S1

M1

S1

.

2 θ

M2

(a)

.

1 θ

Z 1

Z 2 . 1 θ M1

n = = .

Z 2 Z 1 2 θ

M2

.

2 θ

(b)

2 θ

M1

θ 1 (t)

θ 2 = f( 1 )θ

M2

1 θ

(c)

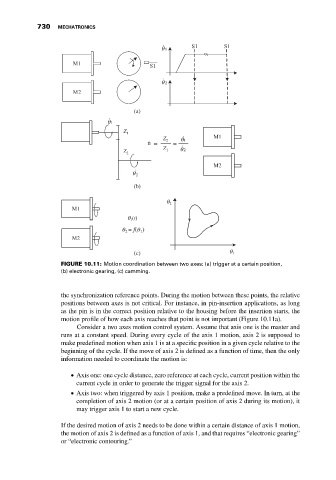

FIGURE 10.11: Motion coordination between two axes: (a) trigger at a certain position,

(b) electronic gearing, (c) camming.

the synchronization reference points. During the motion between these points, the relative

positions between axes is not critical. For instance, in pin-insertion applications, as long

as the pin is in the correct position relative to the housing before the insertion starts, the

motion profile of how each axis reaches that point is not important (Figure 10.11a).

Consider a two axes motion control system. Assume that axis one is the master and

runs at a constant speed. During every cycle of the axis 1 motion, axis 2 is supposed to

make predefined motion when axis 1 is at a specific position in a given cycle relative to the

beginning of the cycle. If the move of axis 2 is defined as a function of time, then the only

information needed to coordinate the motion is:

Axis one: one cycle distance, zero reference at each cycle, current position within the

current cycle in order to generate the trigger signal for the axis 2.

Axis two: when triggered by axis 1 position, make a predefined move. In turn, at the

completion of axis 2 motion (or at a certain position of axis 2 during its motion), it

may trigger axis 1 to start a new cycle.

If the desired motion of axis 2 needs to be done within a certain distance of axis 1 motion,

the motion of axis 2 is defined as a function of axis 1, and that requires “electronic gearing”

or “electronic contouring.”